e-Making Uses Matterport for Historical Preservation, Restoration, and Seismic Retrofitting

Digital engineering firm uses the Matterport Platform to gain efficiencies throughout building information modeling (BIM) and inspection processes

Results

Site surveys performed with 70% time savings and 20% cost savings

Site inspections executed virtually, producing 100% time and cost savings

50x times higher accuracy of measured data, compared to traditional approaches

Built on the Matterport Platform, e-Building produced savings of 80% though efficient management of building documentation aggregated around digital twins

Restoring Italy’s Remondini Palace

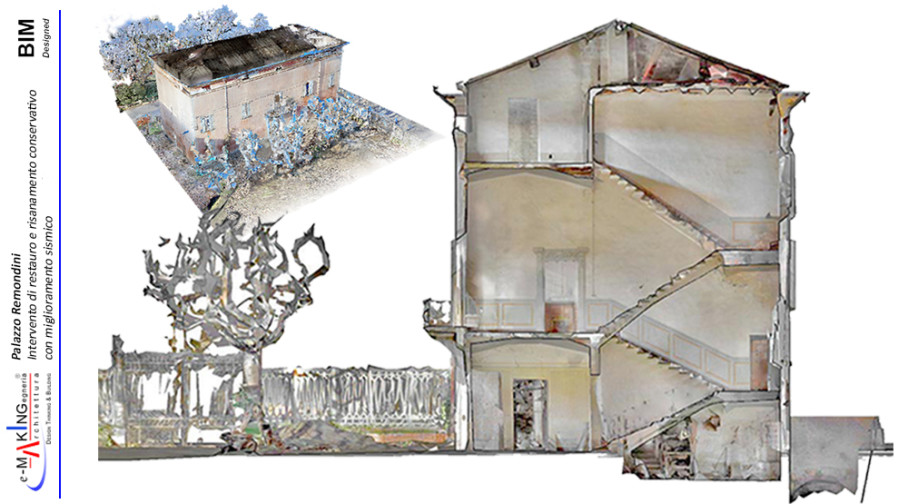

Located in San Giovanni in Persiceto, Italy’s Remondini Palace dates back to 1600 and had sustained serious damage over time as a result of earthquakes in the region. In 2018, the Municipality issued a contingent and urgent order to secure the building, as the property was in extremely critical conditions, in an advanced state of decay with the presence of big collapses. Restoring the Remondini Palace is just one piece of a larger urban redevelopment project spanning the whole of Remondini.

Bologna-based digital engineering firm, e-Making, chose Matterport for improved collaboration throughout the preservation and restoration seismic retrofitting project. First, the group captured digital twins of the Remodini Palace using the Leica BLK360 and the Matterport Pro2 cameras.

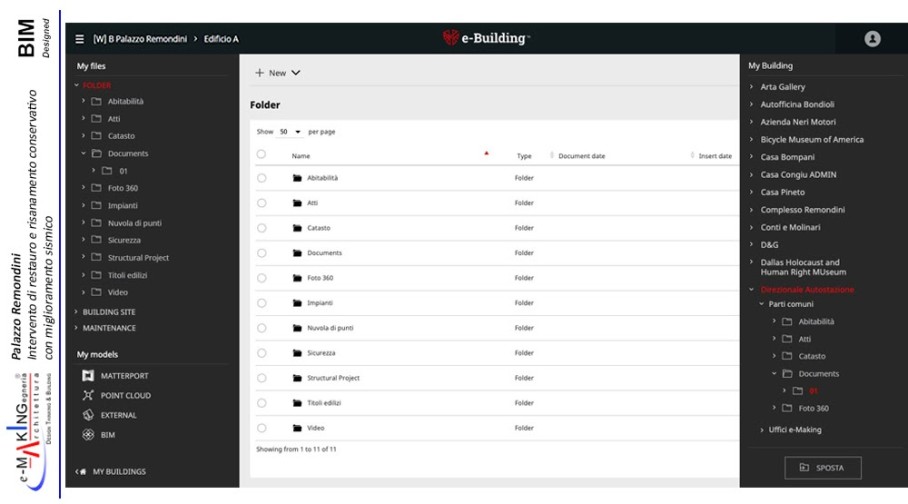

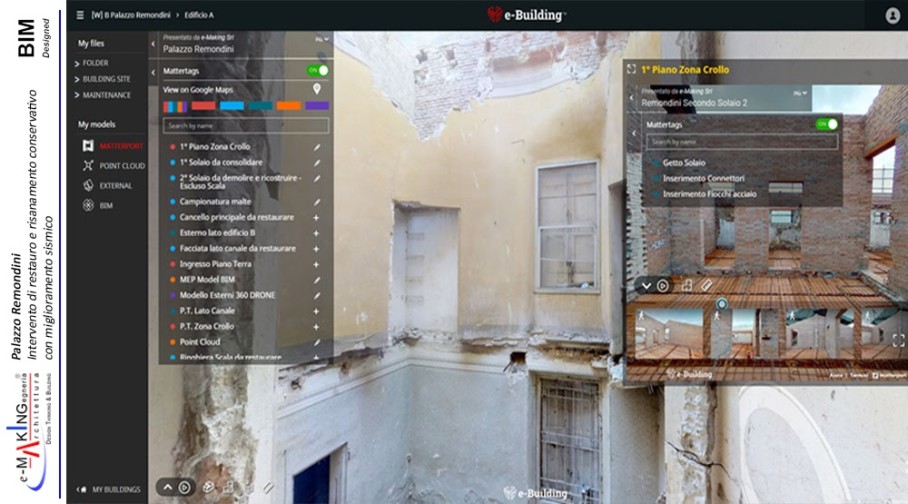

While working on the project, e-Making Principal CEO, Angelo De Cocinis, reverse engineered how the team was archiving and sharing digital twins and building documentation. As a result, De Cocinis utilized Matterport Platform Development Tools to create e-Building, a project management solution that aggregates spatial data from the digital twins.

Users can view, manage, and share archived documentation

Sharing Data Across Design Teams for Greater Efficiencies

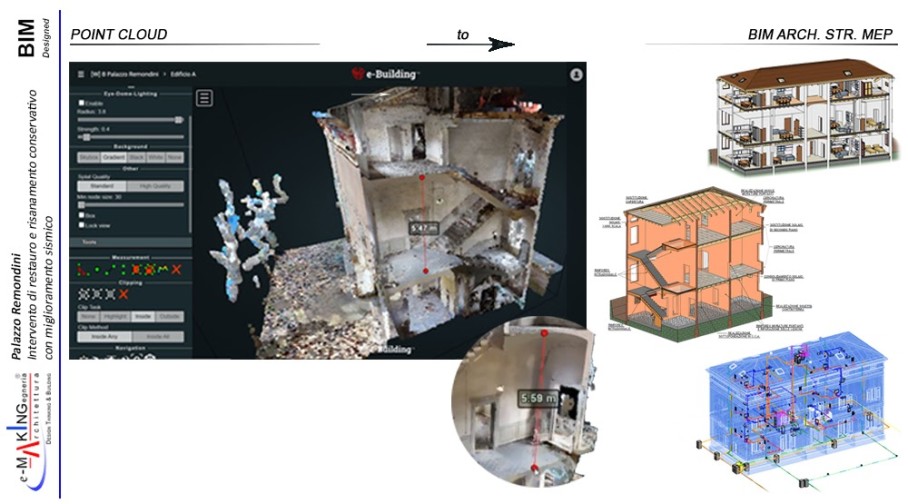

With the e-Building Platform, the e-Making team shared Matterport digital twins of each milestone with architectural, MEP, and structural engineers, so teams could analyze conditions and execute tasks concurrently. The team relied on Matterport digital twins for virtual inspections that helped reduce the time and cost of surveying the property and collecting preliminary measurements.

Check out the full experience here.

“With the Matterport Measurement Mode feature, the team achieved a high degree of accuracy, with a margin of error that was 50 times more accurate than that of traditional methods on highly irregular buildings,” said De Cocinis. “Using Matterport, we performed site surveys in 8 hours using the Matterport Pro2 and Leica BLK360 cameras, achieving 70% time savings and 20% cost savings, compared to traditional survey methods.”

Using e-Building’s enhanced navigation features, the team could analyze elements of the digital twin and work with stakeholders to identify solutions. The team’s notes and other relevant information, including photos, videos and audio files, are embedded with interactive Mattertags that users can easily find and access. Mattertags were essential not only in the initial stages of data collection, but also later during design and construction, as the team constantly updated the digital twins with information.

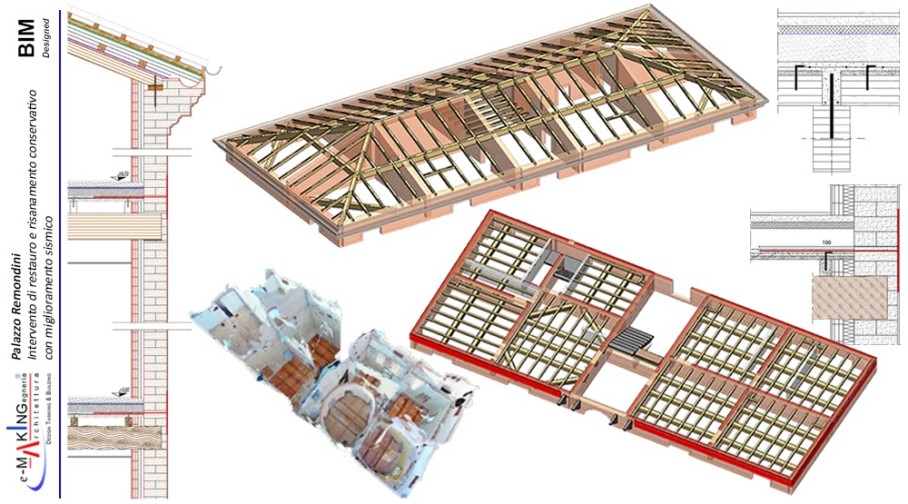

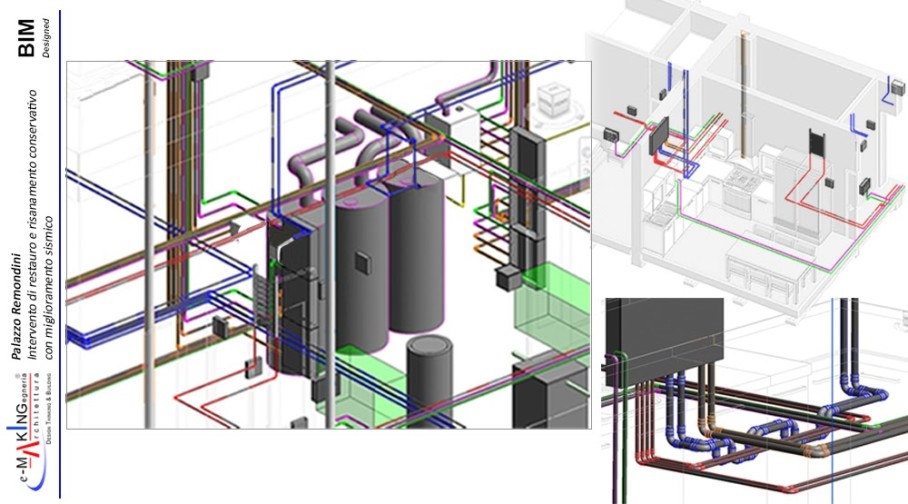

By using Matterport point clouds to execute clash detection tasks in Autodesk Revit in the various phases of the design, the team optimized the mechanical electrical and plumbing (MEP) system distribution and eliminated inconsistencies between the architectural, structural and plant design prior to construction.

Extraction of point cloud from Matterport digital twin used in the BIM design flow

Import point cloud to BIM environment for integrated design workflow

Structural design - interventions on floors and roofing

Thermal power plant located in the under stair closet

More Sustainable Construction and Inspections

“The use of the e-Building makes it possible to manage and share BIM documentation and digital twins of the construction site with the architecture, MEP, and structural engineering team the same day it is produced,” says De Cocinis. “This saves the team 80% of the time and cost associated with accessing and sharing data.”

My models: digital twin view

Site inspections were easier too. Using Matterport, most members of the design team and the companies involved digitally inspected the project site at zero cost, saving 100% of the time and cost compared to physical site inspections.

"We tested a new reverse-engineering design flow with an immersive, navigable Matterport digital twin, which was then enhanced by the e-Building platform. Because the digital twins were searchable, measurable and shareable via the web with the stakeholders, they allowed us to conduct virtual inspections with a remarkable reduction of times and costs,” says Daniele Fanzini, an Associate Professor at Politecnico di Milano. “These tools and the BIM technology together, enable a new way of designing."

Overall, the optimization of the design and management workflow has led to a more sustainable construction process. Now, archives of digital twins and documentation can easily be referenced for the ongoing maintenance and operations of the Remondini Palace so that it can be enjoyed by generations to come.

E-Making is a Matterport Platform Partner that leverages Matterport’s APIs and SDKs to build and commercialize their apps and integrations with our market-leading spatial data platform. As a Platform Partner, they gain access to a range of commercial benefits, such as Matterport’s distribution network and enhanced support as well as co-marketing and co-selling programs to help them successfully monetize their applications. To learn more about the Platform Partner Program and apply to join, visit https://matterport.com/reseller-program.

ABOUT E-Making S.R.L

e-Making S.r.l. is a digital engineering company, established in 2018, that inherits twenty-years experience of the founder, Angelo De Cocinis, and his team, from building design and construction managing at StudioDEG engineering firm. The continuous innovation process has led to the creation of an engineering company, specializing in declined building design, construction process and facility management.

HEADQUARTERS Bologna, Italy

INDUSTRY Engineering - Architectural

CHALLENGE Help architectural, mechanical engineering and plumbing (MEP), and structural engineering teams capture, analyze, and model more efficiently.

PRODUCTS Matterport Pro2 Leica BLK360 Matterport Development Tools

SOLUTION e-Making captured digital twins throughout the project lifecycle for more efficient, accurate building information modeling (BIM) processes and digital inspections. e-Making utilized Matterport Platform Development Tools to develop the e-Building solution for more efficient management of building documentation aggregated around immersive digital twins.

Results

Site surveys performed with 70% time savings and 20% cost savings

Site inspections executed virtually, producing 100% time and cost savings

50x times higher accuracy of measured data, compared to traditional approaches

Built on the Matterport Platform, e-Building produced cost savings of 80% though efficient management of building documentation aggregated around digital twins