Metsä Board Cuts Costs and Manages Construction and Maintenance Projects Faster with Matterport

Boxboard manufacturer captures its mill in immersive 3D for equipment suppliers and project execution

Results

Reduced travel costs and time by 50 percent—and nearly 100 percent in early project stages

More accurate measurements

Faster project initiation

Leaders in Sustainable Energy, Processes, and Products

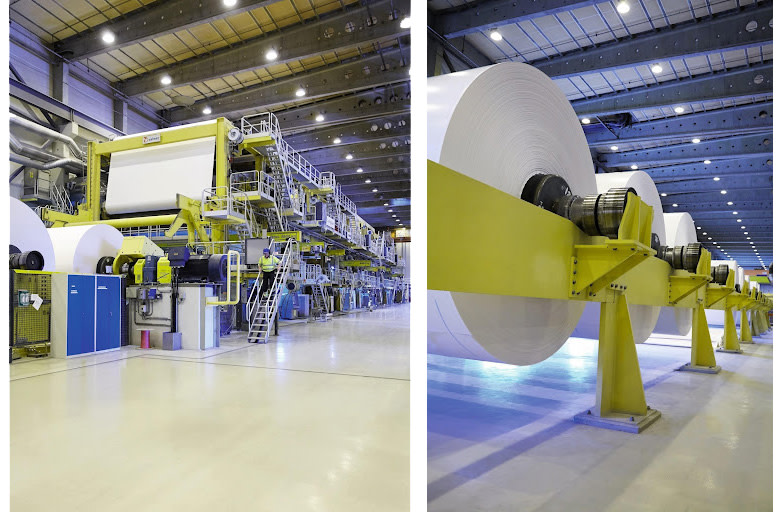

Metsä Board is a Finnish company that makes recycling easy by providing better packaging options that offer viable alternatives to plastic. How? By milling durable and sustainable boxboard and paper board that’s both biodegradable and suitable for direct food contact. Its customers appreciate the ability to provide healthy packaged food while reducing environmental impact as much as possible.

As a leader in sustainable energy, processes, and products, Metsä Board regularly collaborates with AFRY, a Swedish-Finnish consulting firm that’s a global leader in engineering and design. The two companies work together as one team on a variety of manufacturing and operations projects, and they share innovative technologies and techniques with each other. It was in that spirit that AFRY introduced Metsä Board to Matterport.

“We’ve been using Matterport for a couple of years, and we love it,” says AFRY Head of Business Unit Local Project and Engineering Process Industries Sweden, Johan Johansson. “It improves project workflows and improves communication because teams can walk through the digital twin during a project meeting and see exactly what everyone else sees, even when they’re working remotely.”

AFRY has been active in reality capture since the early 1990s, when laser scanning technologies were used in rebuilding projects. Today’s cameras and other equipment are more powerful and less expensive, and AFRY floated the idea of creating a Matterport-powered virtual factory.

Metsä Board was delighted when it discovered what Matterport can do—and how easily and quickly it could implement the solution. “Right away we saw the benefits of bringing this into our business,” says Metsä Board project manager Robert Gidlund, “not only to support major new investment projects but also to support daily operations in the future.”

So Metsä Board decided to create a virtual twin of its Husum mill in Sweden and all its equipment so that vendor supply teams can analyze the mill’s equipment and layout, what it might need to replace, and how everything fits together. It chose AFRY as the service provider and Matterport as the technology supplier. “The first time we used Matterport during a test run to scan the mill, we were up and running in five minutes,” Gidlund says. “We were able to minimize the number of people on site and involve everyone remotely in an incredibly smooth way. And using Matterport completely aligns with our sustainability goals. This solution is here to stay.”

Initiating Projects Faster

Metsä Board is always looking for cutting-edge technologies to boost efficiency. AFRYs use of Matterport helps the company streamline mill equipment maintenance and the replacement of old equipment to increase production.

Metsä Board relies on a variety of suppliers, and the company doesn’t always work with the same teams even when going back to the same supplier for new services. “It’s often a new team,” Gidlund says. “But we can open an accurate, high-quality digital twin during an online meeting and virtually walk through the space, with everybody seeing everything. It’s much better than looking at a diagram of our mill on paper, and there’s no need for in-person visits. It’s a great way to get started quickly without the need to spend the time or cost traveling.”

Travel costs and time have been reduced by 50 percent—and by nearly 100 percent in the early stages. “This was especially helpful during the COVID-19 pandemic when anyone traveling to and from Sweden had to quarantine for a week,” Gidlund explains. “Moving forward, Matterport will also be useful in reducing travel and helping us work more effectively, especially because we won’t have to shout over the noise of the mill.”

Finding ways to enable remote working has long been important for Metsä Board, but it became critical with the onset of the pandemic as the company was planning a project to increase folding boxboard production. During these expansions, project contractors, suppliers, and engineers require real-time information about current conditions.

“Of course information gathered on site is valuable, but this is a terrific alternative and one that contributes to sustainability,” says Gidlund. “Sweden set a goal for zero net greenhouse gas emissions by 2045, and to succeed, we’ll need these kinds of digital solutions.”

Measurements, Mattertags, and Maintenance

In the days before Matterport adoption, Metsä Board spent 20 percent of its pre-production time just taking measurements. Now it doesn’t have to, since AFRY utilized Matterport to capture the spatial data from 3D digital twins.

“We previously relied on photos, but we inevitably missed things and had to go back,” adds Gidlund. “Through AFRY’s use of Matterport, we capture everything with much more detail and efficiency than still photography, plus we can grab high-resolution photos from multiple angles.”

After AFRY scans a space, Metsä Board uses Mattertags to add information and context to specific locations, objects, and features, enhancing communications both internally and with its suppliers and partners. “Before a meeting, I can access measurements, analyze scans, and place Mattertags on the items or objects we’re going to discuss,” explains Gidlund. “As a result, there are now fewer errors because we can highlight critical information.”

Contractors can review details on an ongoing basis and receive information 24/7. Thanks to Matterport, meetings are more effective, misunderstandings are reduced, and safety is improved, all while reducing costs.

Looking Ahead

Because Metsä Board can initiate projects remotely with Matterport, the company will be able to engage with prospective suppliers more easily, sharing digital twins for requests for proposals.

While the pandemic could have delayed Metsä Board’s effort to expand the mill’s capacity through equipment upgrades and enhanced layout, AFRY’s use of Matterport introduced new efficiencies for its employees, suppliers, and customers. “We don’t have to coordinate our schedules as much as we used to,” Gidlund says. “We used to have to wait until everyone could travel on the same date. With Matterport, we avoid that lag time since all our stakeholders can be present virtually.”

As for AFRY, creating digital twins was only the first phase of the virtual factory. Next, AFRY hopes to combine 3D modeling with artificial intelligence and to integrate operational data from manufacturing execution systems.

Now that Metsä Board has saved time, money, travel, and hassle with Matterport, Gidlund says, “We can’t imagine working without it.”

ABOUT METSÄ BOARD

Metsä Board is a leading European producer of premium fresh fiber paperboards. It focuses on lightweight and high-quality folding boxboards, food service boards, and white kraftliners. The pure fresh fibers used in its products are a renewable resource, traceable to origin in sustainably managed northern forests. The company is a forerunner in sustainability, and it aims for completely fossil-free mills and raw materials by 2030.

HEADQUARTERSEspoo, Finland

INDUSTRY Manufacturing

CHALLENGEInitiate construction and maintenance projects faster; reduce costs.

PRODUCTSThe MatterPak Bundle, Matterport Pro2 cameras

SOLUTIONMetsä Board uses Matterport to capture the interior of its mill, including equipment, reducing unnecessary travel and expenses by remotely managing projects.

RESULTS

Reduced travel costs and time by 50 percent—and nearly 100 percent in early project stages

More accurate measurements

Faster project initiation