Space Planning in Facilities Management: Process & Tools

Space planning is the base layer that supports every operational choice in facility management (FM). Every square foot of a facility impacts how productive, safe, and cost-efficient it is. Maintenance routes, staffing decisions, safety reviews, and long-term investments all depend on a clear understanding of how spaces are configured and what they are meant to support.

Yet spatial data is often the least accurate part of the FM stack. Plans drift, drawings fall out of date, and measurements don’t match what’s in the field. As a result, systems struggle to stay aligned with real conditions.

In this guide, we’ll break down what efficient space planning involves and how to create a reliable spatial framework that enables your full FM system to work as intended.

The role of space planning in facilities management

Space planning defines how a facility is organized and used. It establishes the structure for understanding what each area supports, who occupies it, and what resources or clearances it requires to operate safely and efficiently.

A reliable space plan underpins a broad range of activities, including:

Occupancy planning

Maintenance scheduling

Safety reviews and life-safety documentation

Asset placement

Budgeting

Sustainability and energy-use analysis

It also connects these activities across CAFM, IWMS, and CMMS systems so the data they rely on remains accurate. With these systems aligned to accurate spatial data, FM teams will see measurable benefits to how facilities are managed:

Lower move and operational costs: Clear allocations and accurate measurements reduce rework and change-order delays.

Fewer site surveys: Current spatial records minimize on-site checks for equipment installs, renovations, and MAC activities.

Stronger safety and compliance: Verified layouts, egress, clearances, and capacities support audits and reduce life-safety risks.

Better utilization and capacity insights: Underused areas, density risks, and opportunities to consolidate are revealed.

Greater planning agility: Reliable space data helps teams to model changes and respond to operational needs quickly.

Standardized facilities space planning process

To make sure your space planning process is effective for your organization, you need to capture accurate data and maintain a consistent application across workflows. Following this framework will help you to make sure you’re doing just that.

1. Inventory: Capture existing areas and assets

The first step in effective space planning is capturing an accurate inventory of your facility. Be thorough in your audit, noting:

Rooms and workspaces

Assets and equipment

MEP systems

Clearances and circulation

Egress and safety paths

Utilities and service points

Specialized areas

Don’t just document what exists. Make sure to also record how it is currently used and how it interacts with operational workflows.

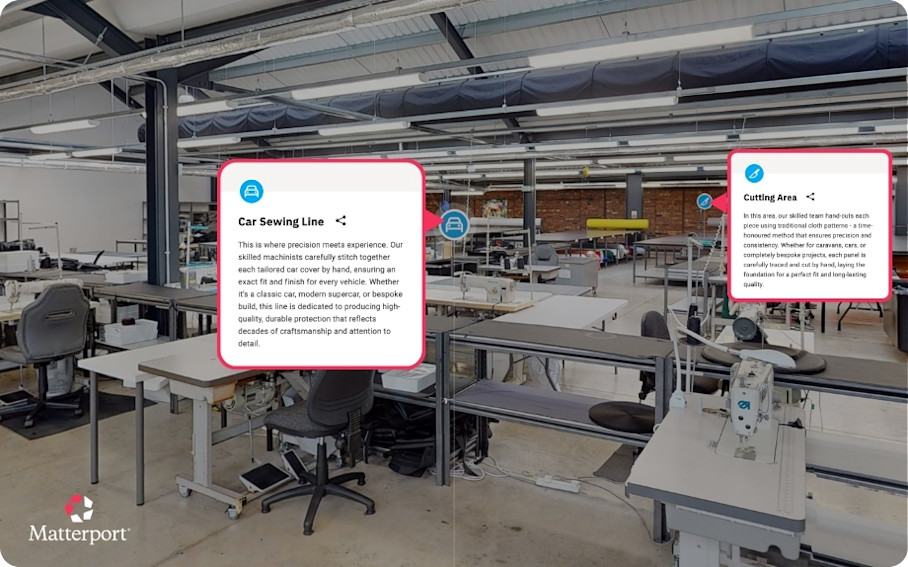

This production facility thoroughly documents different workflow areas.

Capturing all this information manually can be time-consuming and error-prone. Standardize your capture and documentation methods to make it easier to establish a single source of truth and ensure all teams work from the same data.

Using a digital twin as your capture method simplifies the process significantly. A digital twin is a virtual model of your facility that visually records every room, asset, and pathway via 3D scanning. Accurate room measurements, including dimensions, ceiling heights, and layouts, are automatically generated and translated into the digital twin, along with schematic floor plans.

Assets and equipment are visually recorded in the model as well. Notes and Tags can then be added to provide key context like manuals, service history, or warranty information. By using a digital twin as your space and inventory hub, your team will have access to a single source of truth for all future planning and operations.

2. Classification: Standardize data and room types

Once your inventory is captured, the next step is classification: organizing spaces and assets consistently. This ensures that all facility data is meaningful, comparable, and actionable across teams and systems.

Start by defining a space taxonomy that covers:

Space types and codes that define the functionality of the space.

Density targets that define occupancy goals or limits for each space type.

Adjacency requirements addressing which spaces should be located near each other to support workflows (e.g., labs near prep rooms, offices near collaboration areas).

Special use rules that flag rooms with unique functions or regulatory requirements (e.g., chemical storage, medical treatment areas, heavy equipment zones).

Attaching codes, abbreviations, and icons to your taxonomy will make spaces easier to track across systems. By applying these standards consistently, you’ll have a shared language for space, making it easier to allocate resources.

3. Allocation: Link people, functions, and assets to real spaces

Next, you need to map real areas to teams, functions, and assets. This ensures that people have the space and resources they need to work efficiently.

When planning allocations, consider the experience and safety of users. Address common pain points that directly impact how well people are able to do their job or access the resources they need, such as:

Acoustics

Lighting

Ventilation

Safety procedures

Availability of amenities (like storage, lockers, bathrooms, or parking)

For example, an office team assigned to a workspace near mechanical equipment might experience a level of noise that disrupts their focus. Allocations that prioritize comfort and convenience can improve productivity and reduce friction in day-to-day operations.

Adjacency planning is also key. Map common collaboration workflows and organize spaces to minimize travel time and decrease bottlenecks, especially when this may lead to unsafe practices.

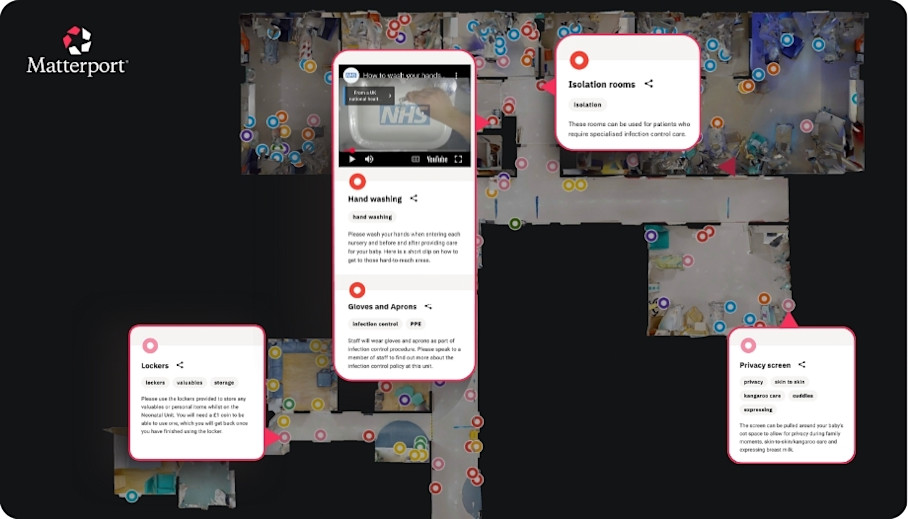

As you map people, functions, and assets to spaces and services, a digital twin can serve as a visual reference. Explore room layouts, asset locations, and circulation patterns in 2D and 3D, to help assign spaces efficiently and attach instructions for space use.

This maternity unit has clearly labelled wash stations next to infection zones clearly labelled, and far from common patient areas.

4. System integration: Connect space planning data with digital workflows

To maximize efficiency, spatial data should be integrated with existing FM tools and systems. Sync layouts, allocations, and asset records with systems like CAFM, IWMS, CMMS, EAM to make FM decisions faster and more reliable.

To integrate effectively:

Assign consistent identifiers to spaces and assets across all systems.

Map corresponding fields so data aligns between platforms.

Set update cadence and ownership using a RACI framework to clarify who updates what and when.

Digital twins deliver verified spatial data assets to feed these systems. Export BIM files to bring floor plans, room dimensions, and asset locations directly into CAD or BIM-based systems for planning, compliance, or construction projects. APIs enable automated syncing of data to FM platforms, so that they reflect real-world conditions at all times.

5. MAC (Move, Add, and Change) workflows: Plan dynamically and reduce site visits

Move, Add, and Change (MAC) refers to the process of relocating teams, adding new equipment, or modifying spaces and assets within a facility.

These activities can disrupt operations if not planned carefully. For example, relocating a team without confirming desk or network access can leave employees unable to work. Adding equipment near critical pathways may block circulation or violate safety clearances. Even small adjustments, like moving storage, can create confusion if changes are not well-planned.

Follow these best practices to give your MAC process the best chance of succeeding from day one:

Map current vs. future layouts: Document existing space usage, then clearly define the new configuration before work begins.

Check dependencies: Confirm that utilities, IT, and MEP connections are available where changes will occur.

Sequence tasks by impact: Plan high-disruption moves outside peak hours or in stages to avoid operational downtime.

Validate compliance and safety: Ensure egress, clearances, and regulatory requirements are maintained for each change.

Coordinate: Provide all stakeholders with detailed layouts and instructions to prevent mistakes on site.

Use your digital twin as a MAC command center: Pin tasks, add attachments, @mention team members to send real-time notifications, and track progress visually.

This approach ensures potentially messy moves, adds and changes happen smoothly and on schedule.

6. Governance and policies: Ensure accuracy and compliance

Space planning carries risk. Without clear governance, one wrong decision could violate accessibility standards or create serious danger to life. Strict regulatory requirements set the boundaries for how spaces can be used and modified.

Establish policies and ownership that ensure every space update keeps the facility safe, compliant, and functional. Key compliance considerations for space planning include:

Egress and fire safety: Verify that paths, doors, and corridors meet local fire codes and maintain required clearances.

Accessibility: Ensure ADA or other regional accessibility standards are met for desks, doors, restrooms, and circulation.

Life safety and occupancy limits: Track maximum occupancy per room or floor and ensure layouts support safe evacuation.

Security zoning: Confirm restricted areas, keycard access, and monitoring systems align with operational requirements.

Equipment placement and clearances: Validate that machinery, storage, and furnishings comply with safety and operational standards.

Documentation: Maintain inspection-ready records of layouts, approvals, and changes to provide a verifiable history.

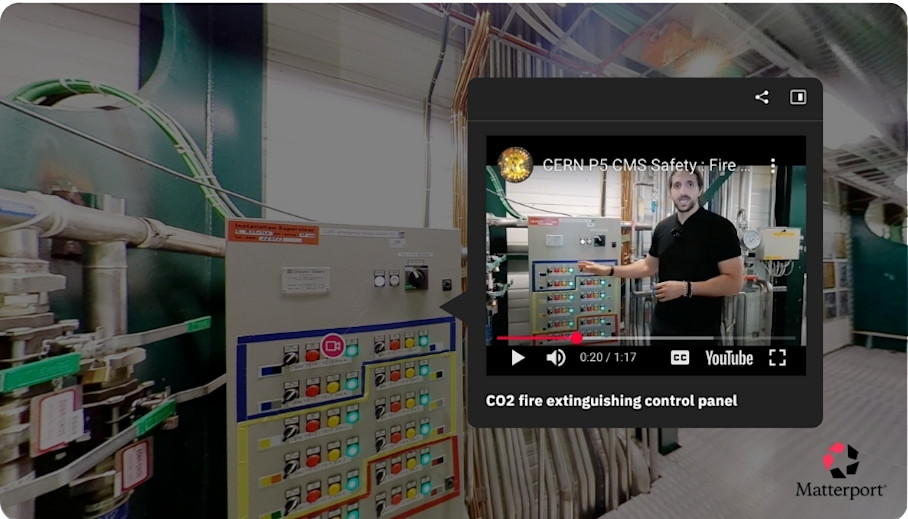

A digital twin will help to demonstrate that your facility data is accurate and up-to-date for compliance decisions and inspections. Use it to:

Annotate egress routes, accessibility features, and occupancy limits directly in context

Archive records of improvements and track changes over time

Share verified information with auditors or stakeholders

This will make your audits faster and simpler, as well as reduce the on-site time required by inspectors to confirm compliance.

The CERN CMS facility team document all safety equipment with location pins and explanatory videos in their digital twin.

7. Reporting and analytics: Turn spatial data into decisions

Applying effective reporting and analytics will help you to plan spaces strategically.

Track key space planning metrics like utilization, density, vacancy and sustainability to uncover inefficiencies or safety risks. Look out for opportunities for smarter space use, such as:

Underutilized rooms with potential for repurposing

Overcrowded areas that suggest the need for additional rooms or staggered scheduling

Inefficient adjacencies that reduce productivity

Redundant storage or equipment areas that could be consolidated

Poorly allocated amenities that don’t align with staff patterns

Energy inefficiencies tied to resources like HVAC or lighting operating in empty areas

Compliance or safety gaps where spaces are not optimized for current use

These insights give FM teams a concrete starting point to reallocate, resize, or redesign spaces, improve productivity, and reduce operational costs.

Adapting space planning to unique facility environments

Certain facility types have unique requirements, from specialized equipment to strict safety or accessibility needs. Let’s explore some examples of distinct facility environments that have additional factors to consider when planning spaces.

Factories and industrial sites

Space planning in industrial environments must account for higher risk and tight operational constraints. Key considerations include:

Equipment footprint accuracy: Machines, workstations, and storage racks occupy critical floor area, and any misalignment may disrupt production.

Safe circulation routes: Forklift paths must stay unobstructed, and aisle widths must meet safety requirements to prevent collisions or bottlenecks.

Overhead clearance validation: Cranes, conveyors, and suspended utilities require verified vertical clearances to avoid equipment conflicts.

Safety cells and separation zones: High-risk machinery and moving equipment demand buffer zones to protect workers.

MEP and utility coordination: Power, air, water, and exhaust drops must be positioned to support operations without blocking access or creating hazards.

Emergency response: Enclosed areas such as pits, tanks, crawlspaces, or enclosed equipment zones must be planned to support crisis protocols like confined space rescue plans.

Industrial space planning evaluates flow, clearance, and risk together—not as isolated elements. Every square foot functions as part of a broader safety system.

A digital twin is a valuable resource in these high-risk environments, providing safe virtual access for space planning and coordination.

Laboratories and R&D

Space planning in labs and R&D facilities requires thorough understanding of highly specialized workflows. Key considerations include:

Controlled zone management: BSL-rated spaces, containment labs, and restricted-access areas must follow strict separation rules and documented boundaries.

Chemical storage and handling: Flammables, corrosives, and gases require compliant storage footprints, clear labeling, and proper distance from ignition or incompatible materials.

Ventilation and fume hood requirements: Airflow direction, hood placement, and exhaust routes must be validated to prevent cross-contamination and maintain safe working conditions.

Utility visibility and access: Gas lines, vacuum drops, power supplies, and emergency shutoffs must be mapped precisely and kept accessible for safety response.

Clean/dirty flow adjacencies: Sample processing, waste handling, and sterilization areas should be arranged to prevent backflow or contamination.

Ultimately, these considerations focus on protecting the integrity of experiments. Space planning decisions should be thoroughly documented to meet compliance requirements and ensure labs are inspection-ready.

Healthcare facilities

Safe patient care is the absolute priority when it comes to space planning in clinical environments. Key considerations include:

Patient and staff flows: Layouts must maintain separation between clean, sterile, and soiled paths, while ensuring unobstructed routes for transfers, gurneys, and emergency response.

Accessibility and life safety: Spaces must meet ADA requirements and align with infection-control protocols for isolation and procedure areas.

Equipment clearances: Imaging devices, exam tables, lifts, and mobile carts require verified footprints and movement radii to avoid bottlenecks and ensure safe operation.

Med-gas and utilities: Medical gas outlets, suction points, power, and emergency shutoffs must be accurately placed and easily accessible relative to beds and procedure zones.

Healthcare is often anything but predictable, so professionals depend on predictable, documented, code-compliant movement and equipment access to optimize procedures.

The fast-paced nature and criticality of these facilities makes it essential for any space planning issues to be resolved before construction or installation begins.

Corporate offices

Corporate offices require flexible planning to support evolving workplace models. Key considerations include:

Hybrid-work utilization: Aligning desk ratios, collaboration zones, and focus areas with real occupancy patterns.

Infrastructure coordination: Positioning IT, power, and HVAC to support reconfigurable work points and modular furniture.

Lease and portfolio accuracy: Maintaining reliable as-builts for tenant improvements, lease negotiations, and benchmarking across sites.

Compared to other facilities, where infrastructure is fixed and reconfiguration is costly, office space planning tends to intentionally be more flexible. Team sizes shift, hybrid schedules reshape desk demand, and new collaboration patterns emerge as projects evolve. These all drive frequent layout adjustments.

Retail and multi-site networks

Space planning in retail and distributed portfolios must balance consistency, customer experience, and operational efficiency. Key considerations include:

Brand-consistent layouts: Store entrances, sightlines, signage, and merchandising zones must follow standardized guidelines to deliver a uniform customer experience across locations.

Accurate fixture placement: Shelving, display tables, and service counters need precise positioning to support both product visibility and compliance.

Efficient back-of-house flow: Stockrooms, receiving areas, and staff routes should be arranged to minimize handling time.

Coordinated rollouts: Remodels, resets, and new store openings require synchronized plans across many sites.

This becomes more complex for large-scale retail teams, who need visibility into layouts and brand standards. Digital twins for retail provide efficient access to every location, helping teams plan at scale.

Education sector (schools and universities)

Educational facilities prioritize safety, accessibility, and highly varied learning needs across a wide range of building types. Key considerations include:

Right-sized learning spaces: Classroom capacities and specialized rooms like labs, workshops, studios, or gyms must be planned to meet varied curricular requirements.

Accessible campus routes: Paths between buildings, elevator access, and ADA-compliant circulation need to support high-traffic break periods across complex campuses.

Campus-wide safety planning: Security zones, wayfinding, and emergency egress paths must remain clear. This is especially difficult in large or historic facilities.

Campus space planning must account for shifting schedules and evolving accessibility and safety requirements, making long-term foresight and flexible layouts critical for effective campus management.

Integrating people, places, and planning with Matterport

Smart facility space planning improves daily experiences for everyone. From safer hospital workflows to productive classrooms and comfortable office zones, when every square foot is purposeful, facilities work harder and people thrive.

Matterport digital twins provide a single, accurate view of every facility space. Explore how Matterport can help your team turn square footage into a smarter, more resilient facility.

Watch our webinar to learn more about how Matterport digital twins support spatial planning made simple.