Pursuing Efficiency in Facility Maintenance: Best Practices That Work

Few businesses can afford their commercial property or equipment falling into disrepair for an extended period. If your HVAC has a breakdown on a hot summer day, tenants' customers might be too busy sweating to consider purchases, or staff may have to go home altogether.

Facility maintenance managers are in charge of making a commercial property run smoothly at all times. It’s a massive industry valued at $78 billion globally, and projected to have a compound annual growth rate of 11.21% between 2025 and 2033. Facilities purchase an estimated $526 billion in products and services each year.

To learn the ins and outs of this important role, below you’ll find a roundup of its many advantages and best practices to help implement your own program.

What is facility maintenance?

Facility maintenance is the upkeep, repair, and management of a commercial building's systems, equipment, and spaces to ensure safe, efficient, and reliable operations.

Maintenance activities include:

Corrective and emergency repairs

Scheduled predictive maintenance

Regular inspections to maintain optimal conditions for occupants and operations

For businesses with brick-and-mortar property and equipment, it’s crucial to have behind-the-scenes processes to keep everything running smoothly. A facility manager will also be responsible for general building maintenance (inside and out), servicing permanent fixtures like HVAC systems, and accomplishing all tasks while staying on budget — a key factor in controlling overall facilities management costs.

While the terms are often used as synonyms, facility maintenance isn’t the same as industrial maintenance or property maintenance. Instead, industrial maintenance specifically applies to manufacturing facilities, while property maintenance is for residential buildings. Facility maintenance typically applies to commercial properties without a manufacturing function.

The 3 types of facility maintenance strategies

When you're managing facility operations, you typically use these three core approaches:

Prevent problems before they start

Predict using data to anticipate equipment needs

Correct to address issues after they occur

By balancing each approach in your maintenance plan, you'll create a safe work environment that operates without a hitch and makes it easy for workers to get things done.

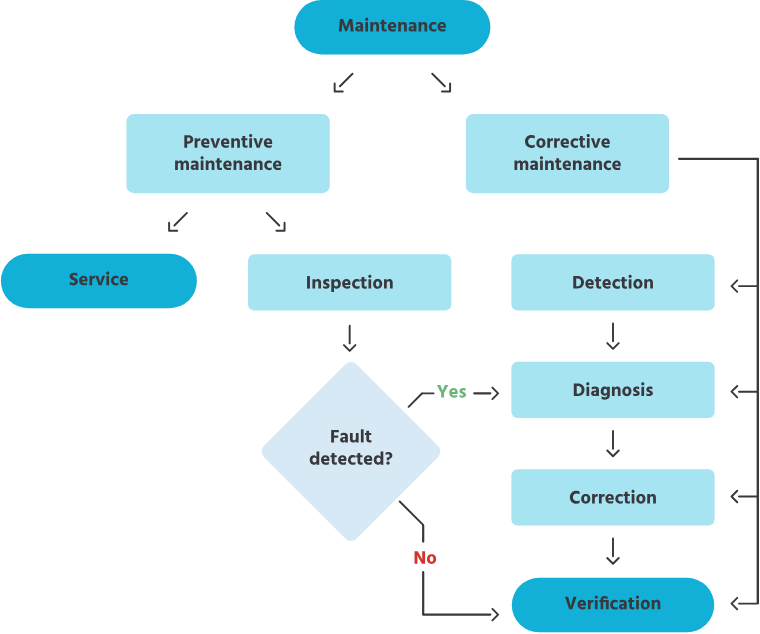

Here’s a visualization of how you might decide on which strategy to use:

Flow chart of when to use different maintenance strategies.

1. Preventive maintenance: Scheduling regular upkeep to prevent failures

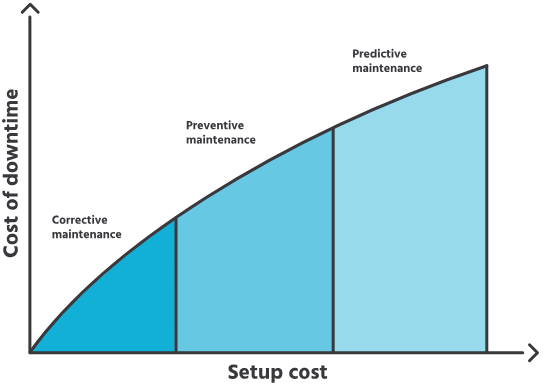

Preventive maintenance follows scheduled intervals to keep your equipment running smoothly before problems develop. This proactive approach helps you avoid unscheduled downtime and critical failures.

Preventive tasks are usually performed at set intervals based on manufacturer recommendations, usage patterns, and expected equipment degradation.

Here are some examples:

Servicing HVAC systems every quarter

Replacing air filters monthly

Conducting annual services of fire safety equipment

This type of maintenance extends equipment lifespan and reduces long-term operational costs. Your maintenance team can plan work schedules efficiently, order parts in advance, and minimize disruptions to daily operations.

2. Predictive maintenance: Using data to anticipate needs

Predictive maintenance uses condition monitoring and analytics to identify potential equipment failures before they happen. Data that’s often monitored includes temperature, vibration, electrical current, and even occupation levels.

Typically, this is done using IoT sensors that feed operational data back to your facility dashboards. This data is recorded and monitored both by software and humans so that problems can be caught as quickly as possible.

This data can be visualized on a digital twin for instant in-context insights like:

Color-coded equipment status showing HVAC units turning from green to yellow when temperature sensors detect overheating, with the exact location and severity displayed directly on the 3D model

Interactive maintenance alerts that let you click on a red-flagged elevator or pump to instantly access sensor readings, maintenance history, and technician instructions without leaving the virtual building walkthrough

Real-time system mapping that highlights affected zones when predictive alerts trigger, showing you which floors or areas will be impacted by equipment downtime before you schedule repairs

A digital twin of a modular containerized compressed air system captured with Matterport Pro2 Camera

Predictive maintenance is a strategy that can drastically improve your operational efficiency as it catches problems as they start (rather than a preventative strategy that guesses when these issues will occur). The benefits can go beyond maintenance too, helping you precisely optimize equipment as environmental factors change, which can have direct and lasting impact on running costs.

3. Corrective maintenance: Resolving issues after detection

Corrective maintenance or reactive maintenance is simply when you fix a problem after you have equipment failure. It follows a 'if it ain’t broke, don’t fix it.’ This is a cost-saving strategy that can work well for non-critical equipment that won’t cause significant downtime.

Corrective maintenance is the most affordable maintenance strategy, but should only be used when there’s a low cost of downtime.

Here are some examples of equipment that could fail, but wouldn’t cause too much inconvenience during operational hours:

Lightbulbs

Decorative water features

Equipment you have multiples of (e.g., 1 of 3 hand dryers in the bathroom)

You'll want to reserve corrective maintenance for non-critical equipment or emergency situations where immediate repair is the most practical solution.

Why commercial properties need facility maintenance

Facility management costs make up a huge chunk of most companies' budgets, so protecting that investment is critical. Without a solid maintenance plan, properties break down unexpectedly, create safety issues, and end up costing way more money when things go wrong.

Well-maintained buildings help organizations attract and keep good employees, create better work experiences, and meet important sustainability goals that require ongoing attention.

Short and long-term cost-effectiveness

All equipment, systems, and buildings deteriorate over time. Just like a car needs regular oil changes and tire rotations to run smoothly, your facility needs routine upkeep to operate efficiently without major breakdowns and expensive emergency repairs.

In 2022, facility maintenance costs skyrocketed. Despite predictions of economic stability, 77% of industry experts still say value for money is the top driver in facility management decision-making for 2025.

How maintenance helps short-term cost-effectiveness:

Scheduled repairs cost less than emergency after-hours service calls

Clean filters and calibrated systems reduce monthly energy bills

Planning ahead lets you buy parts in bulk at better prices

How maintenance helps long-term cost-effectiveness:

Predictable schedules help you budget accurately each year

Regular upkeep can double or triple equipment lifespan

Well-maintained facilities retain higher property values and rental rates

Safety inspections and compliance

Every property has safety best practices to stay compliant with state, federal, and industry standards. Facility maintenance can ensure businesses pass inspections easily and prevent accidents, sickness, or injuries on the property.

That often includes comprehensive fire safety checks for working alarms, sprinklers, and fire exits.

Additional checks will also include:

Natural gas safety inspections

Security alarm testing

Annual electrical checks

Checking plumbing and pipes regularly

Ventilation and air quality checks

Ensuring tenants aren’t violating maximum occupancy rules

Preventing other hazards like icy sidewalks in front of the building

Emergency response and preparedness

In the U.S. alone, there were 27 weather disasters in 2024 that led to $1 billion in damages. Finding ways to optimize your facility's response can make a massive financial impact.

Part of the role of facility managers is to create, maintain, and execute an emergency preparedness and disaster contingency plan for the property and its tenants/residents.

Modern facility managers can enhance their emergency preparedness through IoT sensors integrated with digital twins. When you connect temperature, smoke, and occupancy sensors to your facility's 3D model, you get real-time visibility into emergency conditions as they develop.

Here are some practical examples of how you can prepare for fires, equipment failures, emergencies, and natural disasters by:

Creating safer evacuation routes: Occupancy sensors show which areas have people, while environmental sensors identify hazardous zones to avoid during evacuations

Monitoring critical systems: Temperature and vibration sensors on emergency equipment like fire pumps and backup generators ensure they're ready when needed

Faster emergency response: First responders can access your digital twin to understand building layouts, locate people, and identify the safest approach routes before arriving on-site

Regular system testing: Use sensor data to verify that emergency lighting, HVAC smoke control, and communication systems work properly during routine drills

Pre-loss inventory: By digitally documenting what existed before the disaster, you can drastically speed up insurance claims.

Check out how this 3D scan of a property helped insurers rapidly understand claims in the wake of Hurricane Florence:

Tenant and resident communication

Because so much of facility maintenance happens behind the scenes, tenants and residents often aren’t aware of all this work happening in the background.

Facility managers need to professionally communicate critical information to tenants and residents regarding upcoming safety inspections, emergency preparedness drills, or preventative repairs. That way, everyone is aligned on upcoming work or inspections and prepare accordingly.

Record-keeping and documentation

Proper documentation forms the backbone of effective facility maintenance. When you maintain detailed records of inspections, repairs, and equipment performance, you create a valuable resource that improves decision-making and demonstrates compliance with safety regulations.

Your maintenance records should capture key information about each piece of equipment, including installation dates, warranty periods, service history, and performance trends. This documentation helps you track patterns, predict future maintenance needs, and make informed decisions about repairs versus replacements.

Key benefits of comprehensive documentation include:

Warranty tracking helps you avoid paying for repairs covered under manufacturer guarantees

Service history patterns reveal which equipment requires frequent attention and may need replacement

Compliance records demonstrate adherence to safety codes during inspections and audits

Performance data supports budget planning and helps justify capital expenditures

Digital accessibility allows technicians to access equipment information remotely before arriving on-site

When your documentation is organized within a digital twin platform, maintenance teams can instantly access relevant information while viewing the actual equipment location. This visual approach reduces errors, speeds up repairs, and ensures that critical maintenance information is always available when needed.

Implementing facility maintenance best practices

Now that you have a good grasp on the many benefits of facility maintenance, it’s time to implement a program of your own. But before creating your own facility maintenance process, review these tips to compile a seamless plan for your property.

Digitize equipment info, systems manuals, and warranty data

It goes without saying that you’ll want digital copies of everything related to your job as facility manager, from last year’s service records to compliance documents.

But digitizing is really only the first step. The real value is making sure it’s easily accessible by the right people at the right time. If your facility isn’t too complex, you can do this using a Cloud solution with a folder structure. However, most commercial buildings will benefit from using a digital twin.

Digital twins enhance traditional record-keeping by providing visual context for your maintenance data. You can attach “tags” directly to the 3D mode with equipment manuals, service records, and warranty information.

Now when a technician needs to service a rooftop HVAC unit, they can open up your building’s twin, click on the right tag using the visual interface, and access everything they need. No fuss, no miscommunication, no share permissions.

Best of all, you can access all your documentation remotely, from anywhere.

Create standardized procedures for consistency

Developing clear maintenance protocols keeps your team on track across all building systems.

How to create standardized procedures in your facility

If you don’t have a digital twin, then develop a clear floor plan so you can indicate where everything is located.

All processes can be boiled down to a series of steps. Create checklists for yourself and your team that detail each type of maintenance task, including safety requirements and completion criteria.

Organize your files to create a single source of truth for context like annotations, file attachments, and measurements. This central repository should always be kept up to date using a tool like Cloud storage or Matterport’s digital twins.

Create schedules for repairs and installations

Missed maintenance appointments cost money and create safety risks. Build a scheduling system that tracks preventive maintenance, inspections, and equipment replacements automatically.

Use digital calendars or maintenance management software to set recurring appointments for filter changes, system inspections, and equipment servicing. Share these schedules with your maintenance team, vendors, and facility stakeholders so everyone stays informed about upcoming work.

Improve vendor coordination through shared visual context

Most issues with contractors surface because of communication problems. It’s important that you can clearly and explicitly communicate what you need, why you need it, and where they need to work.

Instead of spending time walking vendors through your facility, send them a direct link to the specific area needing work and do a virtual inspection ahead of time. They can explore the space virtually, measure clearances, and understand site conditions before submitting quotes. This leads to more accurate estimates and faster project completion.

Providing virtual context leads to:

More precise quotes from day one

Faster in-person troubleshooting and repair

Reduced site visits

Ensure industry-specific compliance requirements

Different facilities face unique compliance challenges and regulations to follow. But whether you’re navigating through OSHA or NFPA, your biggest issue is always going to be keeping all your paperwork organized.

For that reason, having a digital twin makes it easy to maintain your compliance status and provides a detailed historical record in case there’s ever any issue. It’s simply all in one place, and thanks to the visual interface, nothing is overlooked.

Below are 3 real examples of how digital twins can help you streamline your compliance.

Example 1: Northfield Public Schools shared digital twins with local law enforcement and emergency personnel so they could learn building layouts before responding to emergencies. Their maintenance team uses the scans to see inside walls for preventive maintenance planning.

Example 2: University of Manchester requires students to complete safety quizzes using digital twin tours before accessing facility spaces. This ensures compliance with safety procedures while helping people with mobility requirements plan accessible routes.

Example 3: Canoa tracks all office equipment with RFID tags mapped to digital twins for environmental compliance. Employees scan QR codes to trigger maintenance tickets, giving service teams instant location context and equipment details. Digital twins helped them reduce site survey costs by 70%.

It’s time to integrate your maintenance systems with 3D visualization

Combining your CMMS with Matterport's 3D models creates a more intuitive workflow than traditional text-based work orders. Instead of describing equipment locations with room numbers and lengthy descriptions, your team can see exactly where work needs to happen.

Link work orders, maintenance schedules, and service history directly to equipment locations in the digital twin. When a pump needs servicing, the work order appears right on the equipment within the 3D model, complete with access instructions and safety requirements.

This integration particularly benefits facilities with complex layouts or numerous identical pieces of equipment. Rather than confusion about "which chiller on the third floor," your team can click directly on the specific unit needing attention, eliminating errors and reducing response time.

Ready to see how digital twins can transform your facility maintenance workflows? Explore Matterport's platform and discover how visual context can streamline your operations.