Guide to Building A Strategic Facility Maintenance Plan: Steps, Tips & Tools

Every year, billions of dollars go into maintenance problems that proper planning could prevent.

When you develop a great facility maintenance plan, you make sure your building is safe and comfortable for the occupant, as well as operationally efficient with minimal downtime.

This guide will show you how to build a maintenance plan using the latest tech that reduces costs, minimizes disruptions, and keeps your facility operating efficiently.

What is a facility maintenance plan?

Optimal performance and efficiency doesn’t happen by accident—it’s driven by a structured approach to maintaining infrastructure, systems, and equipment. That’s where a facility maintenance plan comes in. This plan is updated yearly and is usually reviewed periodically.

A typical maintenance plan includes:

Reports of existing asset conditions and maintenance histories

Staffing levels and requirements with clear roles and responsibilities

Scheduled preventative maintenance activities (such as services or replacements)

Protocols for tracking maintenance work and handling emergency response

Long-term asset management strategies

New technological initiatives for improved risk assessments, compliance, record-keeping, and safety

It’s important to note that “assets” typically refer to systems attached to the building (e.g,. plumbing, elevators, backup generators) and facility maintenance plans don't usually contain assets like work desks or standalone refrigerators unless specifically mentioned.

Maintenance planning has evolved from reactive approaches that wait for equipment to break to predictive strategies that identify problems weeks or months before they turn into breakdowns. These plans use new technologies, software, and AI to help you spot anomalies before they evolve into full-blown issues.

Key elements of an effective maintenance plan and their benefits

Facility maintenance plans exist to avoid the worst-case scenario: downtime. While operational efficiency is a major goal, downtime is what’s most important to commercial operation.

When you look at the costs of downtime, the reason becomes clear:

Fortune Global 500 companies lose 11% of their annual revenue to downtime issues.

Unplanned downtime costs the typical business close to $125,000 per hour.

Building an effective maintenance plan requires several essential components working together seamlessly to ensure comprehensive facility care:

Asset inventory and condition assessment help you budget for the future

Facilities are filled with systems and hardware that need constant maintenance on different schedules. It’s considered good practice to audit the entire facility annually to assess condition and predict replacements.

Audits help you improve your predictions on what needs to be replaced and when. That means you’re always on budget.

By recording the following aspects of each system or asset, you reduce unexpected issues and speed up resolution times:

Age

Current condition

Maintenance history

Operational criticality

Digital tools like CMMS (Computerized Maintenance Management System) software can help you keep track of all your assets, documentation, and schedules. By integrating with a digital twin platform, you can further improve your asset inventory by creating a "living blueprint" of your space, which is easy to update every year. Check out the video below to see exactly how digital twins track your assets:

Preventive maintenance scheduling reduces downtime

Preventive maintenance is when you, a contractor, or a manufacturer predicts the realistic failure point of a system or part.

You can base your preventive maintenance schedule on one of these strategies:

Time elapsed: Perfect for systems with little-to-no fluctuations in operations

Usage: Best for systems that are sensitive to seasonal variations

By setting up regular schedules for services and likely replacements, you save between 12-18% in costs versus reactive strategies.

Documentation and record-keeping protocols make repairs foolproof

When you’ve got instant access to the documents you need, life just gets easier. There’s no fighting about who did what. No confusion because an employee has since quit. No issues with insurance due to a lost document.

To make all your repairs foolproof, make sure you have easily accessible digital documents, including:

Repairs, services, and replacements

Inspections and condition reports

Warranty information

Regulatory compliance certifications and records

While keeping all this in the cloud is a great start, having access to documentation through a digital twin is a game-changer because it bridges the gap between IT and the team that does the actual work.

For example, you can link maintenance records directly to specific locations within your facility using Mattertags. This eliminates time-consuming searches and provides instant visual access to all associated documents. This spatial documentation provides accurate measurements for replacement parts, identifies potential access challenges before work begins, and helps you understand relationships between different systems.

Check out this video to see how it works for yourself:

Team structure and responsibility assignment creates accountability

It’s vital that you define clear roles for all maintenance staff, from managers to specialists to general handypeople. Everyone needs to know who is responsible for what areas so that nothing falls through the cracks.

A clear organizational structure isn’t about hierarchy or a manager being more important than general staff. It’s about creating a culture of accountability and trust. In disaster management, clear team structures can be what saves you from catastrophic downtime.

Pro tip: Embed responsibility information directly into your facility documentation so managers can see who maintains it, when it was last serviced, and when the next service is due.

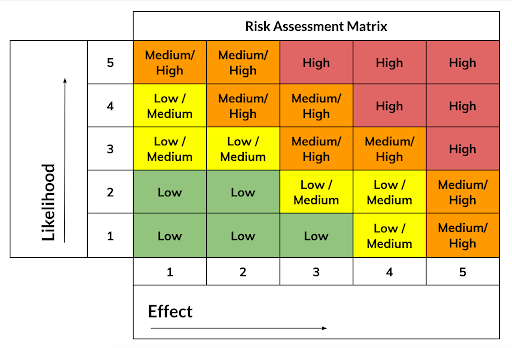

Risk assessments reveal how to prioritize replacements and upgrades

Risk assessments are an essential part of facility maintenance plans because they help you understand what to do when things go wrong.

For each system, you need to understand the failure impact, likelihood of failure, repair costs, and regulatory requirements. From there, you can clearly prioritize replacements in the event of failures, as well as recommend upgrades accordingly.

A risk assessment matrix will help you efficiently prioritize maintenance tasks. (Source)

6 steps to building a facility maintenance plan

Creating an effective maintenance plan requires a systematic approach that builds from solid foundations toward comprehensive coverage.

Step 1: Define maintenance objectives and standards

Objectives and standard metrics help you and your team know what good looks like. Use SMART goals, a method for creating effective and achievable goals by ensuring they are Specific, Measurable, Achievable, Relevant, and Time-bound (aka SMART).

Your goals could look something like:

Achieving 95% uptime for critical building systems within 12 months

Reducing emergency repair costs by 20% within one quarter of the year

Completing 100% of required safety inspections on schedule in Q1

Additionally, KPIs or performance indicators help you track progress on averages for metrics like uptime, mean time between failures, maintenance costs, response times, and repair times.

→ Action: Create a document with SMART goals and KPIs for your maintenance objectives.

Step 2: Assess your facility and current maintenance practices

You need to know what you have, and where it is in its maintenance lifecycle. If you don’t already have an up-to-date audit of your facility, then it’s time to do a walkthrough.

A CMMS will help you schedule preventive maintenance, manage work orders, control inventory, and analyze maintenance data. Ensure your CMMS integrates with your facility documentation to provide visual and historical information.

Use 3D scanning technology to capture your entire facility in photorealistic detail so that you can tag equipment within the digital environment with detailed condition assessments, maintenance requirements, and operational importance ratings.

→ Action: Audit your facility’s assets and upload the data to a CMMS and a digital twin.

Step 3: Prioritize maintenance tasks

Not all maintenance activities are of the same importance. While everything can feel urgent, it’s likely that you have certain priorities that are more fundamental to operations.

It’s a good idea to group your maintenance activities into three categories based on operational impact and safety considerations.

A simple yet effective prioritization matrix groups tasks into 3 categories:

Red: Critical systems that can shut down operations or create safety hazards

Orange: Important but not critical systems that impact comfort and efficiency

Green: Low-priority activities affecting appearance and long-term value

Use the table below for examples of how to categorize maintenance tasks by priority:

Critical maintenance tasks | Important maintenance tasks | Low-priority maintenance tasks |

- HVAC systems maintaining air quality - Elevators and accessibility equipment providing essential building access - Electrical distribution panels and emergency power systems - Main plumbing and water distribution systems

| - Lighting systems - Flooring and interior finishes - Furniture and fixtures - Secondary equipment and convenience systems (e.g., office air conditioners) | - Cosmetic improvements and aesthetic upgrades - Exterior painting and landscaping - Non-operational improvements and enhancements |

→ Action: Divide all your typical maintenance tasks into a prioritization sheet that you can share with stakeholders and your team. Write up definitions for how to categorize unforeseen breakdowns and be clear about how resolution timelines for each priority.

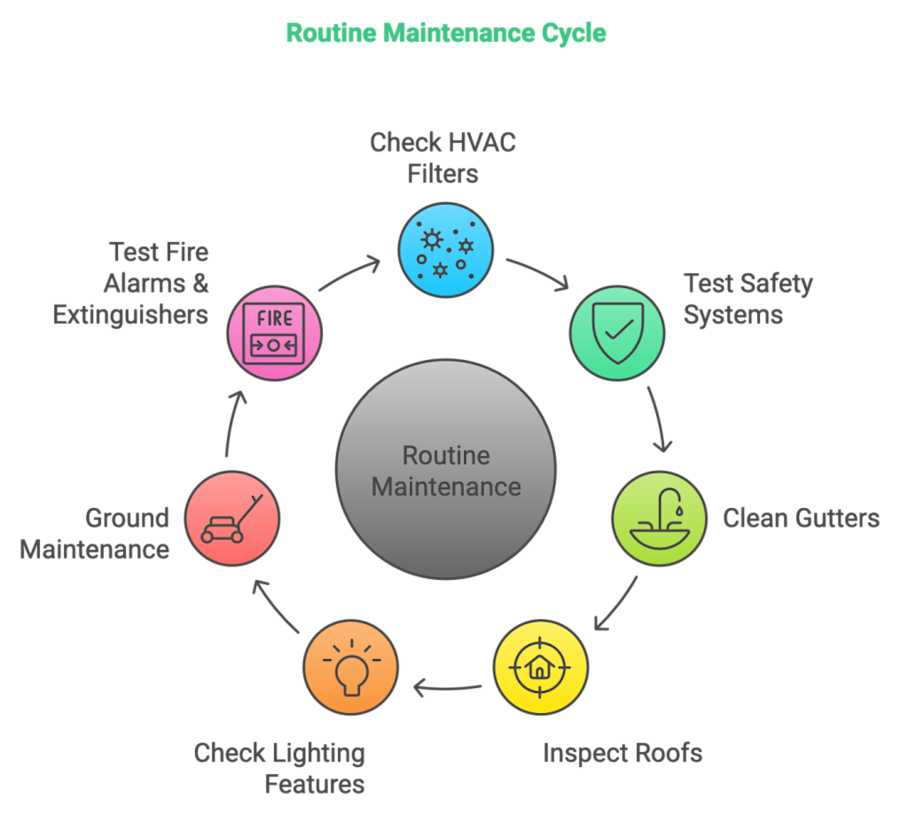

Step 4: Set up a preventative maintenance schedule

Your maintenance schedule is essentially a calendar stating when maintenance will occur. To develop this, start with manufacturer recommendations, then adjust based on your operating conditions. Schedule disruptive maintenance during off-hours, avoid heating system maintenance during winter, and coordinate maintenance affecting multiple systems.

An example of a standard preventative maintenance process (Source)

Use digital twin visualization to plan efficient maintenance routes through your facility, group related tasks together, and identify potential conflicts before work begins.

→ Action: Create a predictive maintenance schedule for a 12-month period. Optimize and supplement this plan using your digital twin by conducting routine inspections virtually to assess equipment condition more frequently without the time and cost of physical site visits.

Step 5: Establish workflow processes and standard operating procedures

You need to establish the staffing levels required to implement your schedule, as well as the approaches your team needs to take.

As your plan matures, provide visual context for maintenance instructions through digital facility models. Instead of written descriptions, technicians can access comprehensive visual references showing exactly where equipment is located and how to access it safely.

→ Action: Create detailed SOPs for routine maintenance tasks with:

step-by-step procedures

emergency response procedures with immediate actions and contact information

work order management covering request submission and completion tracking

communication protocols for updates and notifications

Step 6: Implement technology solutions and continuous improvement

To become one of the most trusted brands in the world, Toyota uses the Japanese concept of “Kaizen,” meaning continuous improvement. You can implement the same culture in your own facility by scheduling regular reviews to improve operations.

→ Action: Conduct regular plan reviews monthly for operational issues, quarterly for tactical adjustments, and annually for strategic planning. Update facility scans to reveal changes affecting maintenance planning, such as new equipment installations or space modifications.

Examples across industries: A tailored plan for your facility

Whilst core maintenance principles stay the same across facilities, different industries require specialized approaches. Below we explore the requirements of five different industries and offer guidance on how you might want to tailor your maintenance plan.

Commercial building maintenance

Commercial building maintenance focuses on tenant comfort and satisfaction while maintaining common areas and critical building systems. Facility managers must balance multiple tenant needs, coordinate maintenance around business operations, and maintain professional appearances.

While that sounds like the simplest version of facility maintenance, the large number of people moving in, out, and through a space creates some interesting challenges.

Specifically, you need to plan for:

Balancing the needs of the tenant with the needs of the landlord

Coordination of maintenance that doesn’t obstruct the tenant's ability to conduct their business

Maintaining the professional appearance of your staff and operations at all times

For example, PlanOmatic, a property management company, struggled with long maintenance planning times and disputes with tenants. By using 3D scanning to create detailed visual records of each property's condition before and after tenant occupancy, they instantly streamlined maintenance, resulting in:

40% reduction in maintenance disputes between property managers and tenants

60% decrease in facility maintenance planning time

Improved accuracy in maintenance cost estimates and scheduling

Manufacturing facility maintenance

Manufacturing facility maintenance operates under intense pressure because every minute of unplanned downtime directly impacts production output and revenue. Unplanned downtime costs industrial manufacturers as much as $50 billion annually, making equipment reliability the top priority for facility managers.

Unlike other facility types, manufacturing maintenance must work around continuous production schedules while ensuring worker safety and equipment reliability. The unique challenges include:

Scheduling major maintenance during limited production breaks and downtime windows

Managing complex interdependencies between production equipment and support systems

Maintaining strict safety protocols, including lockout/tagout procedures for production equipment

Did you know? 60% of maintenance professionals cite skilled labor shortage as the top challenge in manufacturing environments, making efficient planning and documentation even more critical for these facilities.

Multi-site property portfolio strategy

When you’re managing three or more facilities and need to provide the same experience in different locations, your maintenance plan should:

Balance standardization and flexibility

Manages resources across geographic distances

Coordinates teams across locations

Maintains consistent documentation

Accounts for specific site differences like climate and local compliance laws

Danone, the global food and beverage company, needed to coordinate maintenance across manufacturing facilities worldwide with strict safety protocols. By implementing digital twins across their facilities, they created a standardized approach to virtual facility access and maintenance planning, resulting in a 50% reduction in in-person site visits and saving 4 hours a day in planning.

Design and construction projects

Construction project maintenance planning begins during the design phase to ensure long-term operational efficiency. Here are two key examples:

Example 1: Metsä Board

Metsä Board captured 3D scans at key construction milestones, creating a comprehensive record of system installations and component locations.

“It improves project workflows and improves communication because teams can walk through the digital twin during a project meeting and see exactly what everyone else sees, even when they’re working remotely.” Johan Johansson, AFRY Head of Business Unit Local Project and Engineering Process Industries Sweden.

Here are the results Metsä Board reported:

75% reduction in maintenance planning time

50% decrease in maintenance errors

Comprehensive visual documentation of all system installations

Example 2: SIMLAB

SIMLAB embedded IoT sensors throughout the facility and linked sensor data to specific equipment locations within their 3D model. They saw:

30% reduction in unnecessary maintenance tasks

25% improvement in equipment uptime

Here’s a video walking you through how they did it:

Healthcare facility maintenance

Healthcare facility maintenance operates under strict regulatory oversight with patient safety as the primary concern. Maintenance teams must navigate infection control protocols, work around patient care schedules, and maintain life-safety systems that directly impact patient outcomes.

Critical considerations include infection control protocols affecting all maintenance work in patient areas, life-safety systems like medical gas and emergency power that cannot fail, regulatory compliance from multiple agencies with overlapping requirements, and 24/7 operations that create complex scheduling challenges around patient care activities.

Get started by exploring how digital twins can enhance your facility maintenance plan

Digital twin technology can transform how you document, plan, and execute maintenance activities by providing comprehensive visual documentation and real-time collaboration capabilities.

Schedule a demo today to see how Matterport can help you create a more efficient, cost-effective maintenance program for your facility.