Digital Twin in The Supply Chain: Taking Facility Coordination To The Next Level

When managing a supply chain, you need a clear view of how everything fits together, including inventory, infrastructure, and workflows. If you’re under pressure to cut costs, stay precise, and move faster, digital twins can give you a competitive edge.

A digital twin is an immersive 3D model that transforms your physical facility into an interactive, dimensionally accurate digital environment that teams can explore anywhere.

What makes a digital twin so valuable is its connection to live data captured within your building. This means you can:

Visualize your entire network in one place

See current inventory and asset locations

Simulate changes to predict outcomes before implementing them

Identify bottlenecks and disruption risks automatically

Optimize operations using AI-powered recommendations

Read on to discover how to optimize your logistics with cutting-edge photogrammetry technology.

9 ways digital twins streamline your supply chain management

Digital twins are a supply chain powerhouse that fundamentally changes how you access, understand, and manage your network.

There are four types of digital twins, each serving different operational needs:

Component Twins represent individual parts, like sensors or valves, for detailed monitoring.

Product/Asset Twins model complex equipment by combining multiple component twins.

System Twins simulate how different assets work together as functional units.

Process Twins provide end-to-end visibility by connecting multiple systems.

When all these types work together, logistics runs better with easier maintenance, stronger performance, better system setups, and testing that doesn’t interrupt daily operations.

1. Unprecedented visibility across your facilities

Capturing digital twins of your facilities simplifies site management by giving you a clear, remote view of every location.

With immersive 3D models, you can quickly spot issues and make smarter decisions based on real-time conditions. Unlike static floor plans or spreadsheets, these detailed captures provide rich, actionable data that helps teams inspect and maintain sites across the network. Digital twins show exactly what’s happening on the ground, helping solve urgent supply chain issues faster.

Global food giant Danone scanned their production facilities in 3D so everyone could see the same thing, no matter where they were working from. "We needed a way for our teams to visit sites without having to travel, suit up, complete specialized training, or risk cross-contamination," explained Stuart Grace, a digital innovation manager for Danone in Wexford, Ireland.

By implementing Matterport’s ecosystem of smart building tools, Danone reduced in-person site visits by 50%, saved hundreds of employee hours annually, made more informed decisions during online meetings, and shortened project timelines by weeks while enhancing employee training through virtual factory tours.

A 3D representation of Danone’s Nutricia Factory in Haps, Netherlands, captured using Matterport Pro3 cameras

2. Improve team communication and collaboration

Digital twins put everyone on the same page with a shared visual understanding of your operations. Staff from different countries can look at the same spot in your warehouse together. No more confusion about which location you're talking about — everyone sees the same visuals, documentation, and data.

Using tools with tagging capabilities, you can:

Mark specific equipment, pallets, or inventory areas with detailed notes

Attach photos, documents, and relevant links to exact locations

Create guided tours highlighting critical areas for vendors or contractors

Add measurement annotations for precise planning

Check out how easy it is to add a tag in this video:

An interactive environment cuts through the confusion that slows down teamwork, especially when running facilities in different locations. Now, your colleagues can walk through facilities together regardless of physical distance and hand off projects smoothly with clear visual instructions.

3. Optimize warehouse layouts, transportation routes, and facility logistics

The most powerful feature of 3D modeling technology is the ability to experiment without physical changes. You can move equipment, redesign workflows, and test transportation routes—all virtually. This simulation capability lets you identify inefficiencies and bottlenecks without disrupting daily operations.

With this technology, you can optimize your entire logistics network:

Maximize storage density while preserving necessary access lanes

Plot optimal shipping routes based on actual facility constraints

Simulate loading dock traffic during peak periods

Test equipment placement before installation

Analyze traffic patterns to reduce congestion points

Consider how this virtual testing eliminates costly trial-and-error approaches. Instead of physically rearranging shelving or redrawing delivery routes repeatedly, you can test dozens of configurations digitally, selecting only the most efficient for implementation.

4. Simplify inventory and asset management

When you document the exact location and condition of your inventory, equipment, and materials, you streamline operations and take full control of your asset management. This reduces inventory loss, boosts accountability, and helps you locate assets and materials quickly, even in the most complex facilities.

By integrating digital twins with BIM systems and IoT sensors, you can track critical factors like temperature, humidity, and equipment status in real time. All this data flows into a single, immersive interface, making it easy to streamline decision-making and improve every part of your asset management process.

By connecting physical spaces with digital data, your team stays ahead of potential issues before they disrupt operations or cut into your revenue.

5. Effortlessly track training, documentation and compliance

The power of digital twins is the integration of facility operations, records, and history into a single, spatial system. Rather than managing separate documentation systems, training programs, and compliance checklists, everything connects through the visual model of your facility.

This immersive approach revolutionizes how teams learn, document, and comply with regulations:

Training: New associates explore interactive facility models with embedded instruction points. According to PwC, companies using immersive training technologies like virtual reality can train employees up to four times faster than in classroom settings and with greater retention.

Documentation: Maintenance teams access equipment histories through spatial tagging, eliminating the hunt through disconnected systems. Each critical asset can be linked to manuals, repair records, and performance data—all accessible directly within the virtual environment.

Compliance: Regulatory adherence becomes visual and verifiable. Safety inspectors can conduct virtual walkthroughs to verify proper signage placement, access to emergency equipment, and conformity with spatial requirements. Historical records provide time-stamped visual evidence of compliance measures.

6. Future-proof for expansions and tech adoption

With a 3D model of your facility, you can verify spatial clearances, check utilities, and confirm access points before installation begins. This high-accuracy reference streamlines collaboration, prevents errors, and supports more efficient asset management from the start.

Beyond day-to-day operations, digital twins act as a living historical record of your facility. By capturing site changes, deliveries, and storage conditions over time, you build a reliable visual timeline that strengthens both compliance and inventory control.

Teams can easily reference this documentation to verify installation details, track maintenance history, and provide detailed evidence for audits or insurance claims processing. When regulators require proof of compliance, you’ll have visual records ready to share—making inspections faster and less stressful.

7. Future-proof for expansions and tech adoption

From a single warehouse to a global distribution network, accurate 3D models help you identify logistics bottlenecks efficiently. When adding new technologies or expanding facilities, you gain:

Precise spatial information for planning instead of estimates

The ability to simulate changes before implementation

A unified system that grows with your distribution network

Tools to identify and address bottlenecks before they impact operations

A platform for integrating emerging technologies like automation and AI

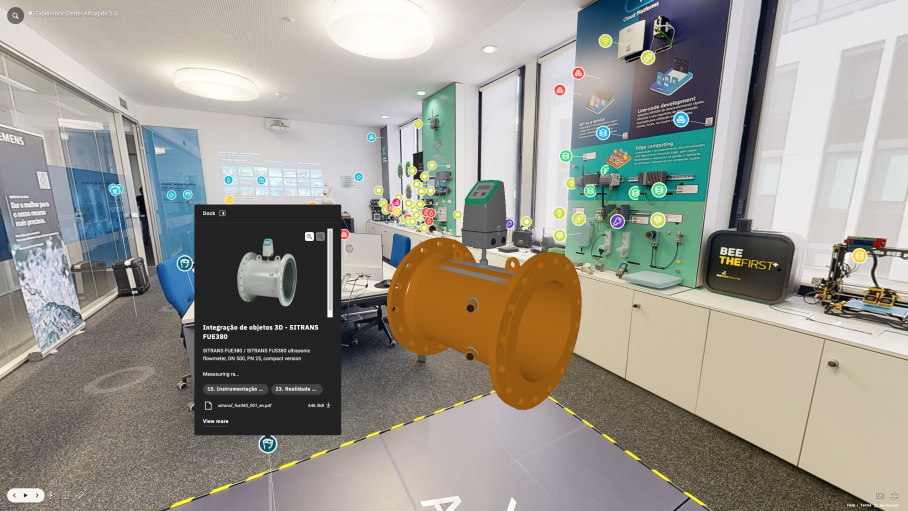

Siemens demonstrates this by using digital twins to scale their global operations while maintaining alignment across departments. They've achieved remarkable results:

Scanned a massive 4,000 m² factory for virtual customer tours

Created a Lisbon campus digital twin viewed over 20,000 times by stakeholders

Integrated IoT sensor data for improved operational insights

"We saw an opportunity to provide immersive, intuitive experiences that were far superior to photography and an inexpensive alternative to other scanning solutions," said Alexandre Piedade, Incubation Manager at Siemens.

Click here to open up Siemen’s the interactive experience

7. Predictive analytics and risk management

What happens to your operations if a key supplier's facility floods? Or when holiday demand spikes 30% above forecast? Virtual scenario testing answers these critical questions before problems arise.

Your immersive models become powerful prediction tools:

Visualize inventory depletion rates under different demand patterns

Develop comprehensive disaster recovery plans with visual guidance

Test emergency response procedures in a risk-free environment

Create backup supplier integration plans with clear visual instructions

This capability is particularly valuable for disaster recovery and emergency planning. Teams can pre-visualize evacuation routes, establish clear protocols for equipment shutdown procedures, and coordinate complex emergency responses—all virtually before implementation. When actual emergencies occur, staff can reference familiar visual guides rather than trying to interpret text-heavy manuals under pressure.

8. Energy usage and sustainability tracking

Creating more sustainable, smart buildings requires understanding exactly how resources flow through your facilities. Digital twins make this possible by transforming complex sustainability data into intuitive visual patterns anyone can interpret.

This visibility empowers practical environmental improvements:

Identify areas consuming excessive heating or cooling energy

Model daylight harvesting opportunities for natural lighting optimization

Track waste reduction initiatives with visual before/after comparisons

Monitor smart building systems for optimal performance

9. Improved supplier performance monitoring

Digital twins transform how you track supplier performance by bringing all vendor data into one visual system. Quality metrics appear as easy-to-read heatmaps, while delivery performance shows up in intuitive charts that highlight patterns instantly.

This shared visibility benefits both sides. Your team spots issues faster while suppliers gain clarity about how their components integrate with your operations. No more confusion about requirements or performance expectations.

According to McKinsey, "Digital twins combined with SCM tools can test for a distribution of potential scenarios by analyzing metrics, such as lead time, demand, and supplier reliability, while also considering what-if outcomes." Their research found that companies using these capabilities have reduced transportation costs by 5% through better coordination and faster problem resolution.

How to implement a digital twin in your supply chain management

Want to create your own 3D model of your facility and supply chain operations? Here’s a 5-step roadmap so you know what to expect.

Step #1: Assess current data sources and equipment

Begin with your current systems. Understanding what tools and data you already use helps you plan better. Start by:

Listing your inventory systems, sensors, and planning tools

Checking what equipment tracking you already have

Finding gaps or overlaps in your current systems

TIP: Tools like Zapier or MuleSoft help connect your existing systems.

Step #2: Define clear objectives and scope

Pick a solution that fits your business. Your ideal system should be easy to use, work with your other tools, and grow with you.

Define what you want to improve:

Is your warehouse layout inefficient?

Do you lose track of inventory?

Does your workforce struggle to work together across locations?

TIP: Matterport makes capturing and sharing 3D spaces simple, even for complex facilities.

Step #3: Capture physical spaces and connect your data

Scan your space with a 3D camera or even a smartphone to make an accurate digital copy. Next, connect your important information:

Add your floor plans

Link real time sensor readings

Include equipment details

Connect up-to-the-minute data from temperature monitors or RFID tags

TIP: An API will automatically connect your data feeds to your 3D model.

Step #4: Launch a pilot project and evaluate impact

Before going all-in, test your digital twin on a small scale. Measure the results carefully. Track and compare changes for time, costs, and mistakes.

Pick a specific area to improve:

Optimize one zone at a time

Track high-value assets in a certain section

Improve training for one department

TIP: Use Power BI or Tableau dashboards to visualize your improvements.

Step #5: Scale across facilities and refine strategy

Roll out to more areas. Continue collecting user feedback, refine your approach based on real-world results, and improve system integrations.

As you expand:

Keep collecting feedback from users

Refine your approach based on real-world results

Improve how your connects with other systems by adding integrations

TIP: Project tools like Asana, Monday.com Supply Chain, or SAP Integrated Business Planning help track your expansion plans and next steps.

Unlock your supply chain potential with Matterport’s immersive 3D digital twins

Matterport's digital twins give you unprecedented control over your operations. With photorealistic 3D captures and AI-powered insights, you'll make smarter decisions faster while cutting costs and improving collaboration across your entire logistics network.

Ready to revolutionize your supply chain? Start by contacting Matterport Capture Services.