A Practical Guide to IIoT Automation for Facility Management Leaders

Facility managers carry a lot on their shoulders. Equipment performance, energy efficiency, and operational safety all rely on constant attention—often requiring boots on the ground.

But industrial automation is changing that.

Currently, we’re in the middle of phase 4 of industrial automation. This phase is called Industry 4.0, and its vital technology is the Industrial Internet of Things or IIoT.

IIoT technology connects data from equipment, sensors, and systems into one intelligent network. It moves facility management from reactive to proactive by enabling real-time monitoring, predictive maintenance, and smarter decision-making from anywhere. Unlike consumer IoT, which focuses on convenience, IIoT is built for critical infrastructure and business impact.

This guide breaks down how to implement IIoT automation processes in a way that’s practical, scalable, and focused on results. It covers the steps to assess readiness, select the right tech, build a data system that works, create digital twins, upskill teams, address security, and measure performance.

Why is IoT the engine behind modern industrial automation?

IoT is often described as the engine behind modern industrial automation—but a better comparison might be your body’s nervous system.

It continuously monitors your facility’s “vital signs” through sensors embedded in equipment and infrastructure, transmitting real-time signals that trigger immediate, automated responses—whether it’s a maintenance alert, a system shutdown, or a process adjustment to avoid downtime.

Unlike consumer IoT devices that connect smart home appliances, industrial IoT (IIoT) is built for scale, durability, and precision. It’s designed to improve productivity, safety, and efficiency by layering real-time data and automated control systems across critical operations.

For example, in a manufacturing plant, an IIoT system might include vibration sensors on motors to detect wear, temperature and humidity monitors to ensure product quality, and connected control systems that automatically adjust production speed based on line performance. All of this data flows into a centralized platform—often a digital twin of the facility—giving operators a live, visual map of the factory floor to spot issues before they escalate.

Key benefits of IIoT automation in facility management

IIoT automation addresses efficiency issues head-on by giving you the visibility and control you’ve been missing. It connects previously isolated systems and equipment to a centralized monitoring platform. This real-time connectivity creates a continuous stream of operational data, enabling smarter decisions and more efficient day-to-day operations.

Beyond general improvements in efficiency, an IIoT automation system delivers the following benefits:

Predictive maintenance & reduced downtime: Spot equipment issues early and prevent costly failures before they happen.

Improved safety & compliance: Continuously monitor hazardous conditions and ensure adherence to regulatory standards.

Energy optimization & sustainability: Track usage patterns to identify waste, lower energy bills, and support green initiatives.

Smarter space utilization: Analyze occupancy data to optimize layouts and reduce underused areas.

Remote monitoring capabilities: Gain instant access to operational data—anytime, anywhere.

Lower risk in retrofit projects: Virtually test upgrades or changes before making them live.

The true value lies in shifting from reactive maintenance to proactive facility management. By leveraging performance data, you can anticipate needs, extend asset lifespans, and boost overall reliability.

The 7 steps of IIoT automation

Success requires a structured approach that matches technology to your facility's specific needs.

To implement any IIoT system, you’ll need to follow a timeline that loosely follows the steps below:

Evaluate your current infrastructure, identify high-value opportunities, and set clear objectives.

Select sensors that balance your range, bandwidth, and power requirements.

Scale by blending edge and cloud computing while ensuring integration with your existing platforms.

Enhance your data's value by establishing a visual context that makes information more intuitive and actionable.

Prepare your team with the technical and operational knowledge they need to maximize your IIoT investment.

Protect your connected systems from threats with comprehensive risk assessment and appropriate safeguards.

Track your results against clear baseline metrics and adopt an ongoing improvement mindset.

Let's explore each step in detail so you can implement IIoT with confidence and avoid common pitfalls.

1. Assess your facility's readiness

Before buying any hardware or software, take stock of what you have and what you need.

Start with a tech audit that answers these questions:

Which systems would benefit most from remote monitoring?

Can your current network handle more connected devices?

Will your building systems work with IoT integration?

What data would be most valuable to collect and analyze?

Next, create a simple chart that plots potential projects based on how hard they are to implement versus their expected benefits. This helps you pick the right place to start.

Set clear goals from the beginning—like cutting energy use by 15% or reducing maintenance costs by 20%. Without specific targets, you can't measure success.

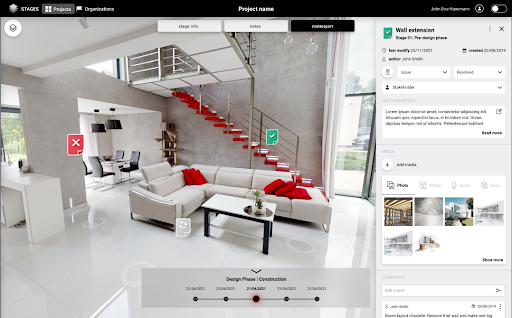

SIMLAB is a good example of how important this step is. They started with thorough facility assessments, finding the most critical systems and setting baseline metrics before installing a single sensor. Now they have robust dashboards like the one you see below.

A snapshot of SIMLAB’s digital asset information and maintenance scheduling system.

2. Select the right sensors and connectivity options

The sensors you choose directly affect the quality and usefulness of your data.

There are 2 main types of sensor groups you need to consider:

Environmental sensors track temperature, humidity, air quality, and occupancy. These help with comfort and meeting regulations. You often need many of these throughout your facility.

Equipment sensors measure vibration, temperature, pressure, and power use. These help you catch problems before equipment fails. Place these on your most critical machines.

There are many ways to connect your sensors to the IoT, and the option you choose will depend on your budget, facility size, and reliability requirements. In your search, ask providers about the following options:

Wi-Fi: Good data speed but uses more power

Bluetooth Low Energy: Uses less power but has a shorter range

LoRaWAN: Long range with low power needs, great for large facilities

5G: Becoming better for industrial uses needing fast data transfer

Colgate-Palmolive, for instance, improved efficiency by 15% by focusing on flow sensors for compressed air systems. Since compressed air can use up to 30% of industrial energy, this was a smart first step.

3. Build a scalable data system

A well-designed system lets you add modular capacity, easily scaling. A limited system will require complete renovations for you to upgrade capacity. So choose the one that will still be compatible 5 or 10 years in the future.

Your first decision is on-premises or remote data storage and processing. Solutions like edge computing and cloud computing are vital to your operations and many facilities employ a hybrid operating system where:

Edge handles real-time, mission-critical tasks

Cloud handles deeper analytics, storage, machine learning model training, or long-term insights

A key step is ensuring your IIoT platform integrates with existing systems like your BMS, maintenance software, and resource planning tools.

Amazon’s Executive Briefing Center connects IoT data with Matterport’s digital twins, providing a unified platform to monitor operations, equipment, and conditions. With this approach, you have a complete 360 view of your facility in real time.

4. Create a digital twin strategy

Digital twins are virtual copies of physical spaces that serve almost as an augmented reality experience for your data. They make it instantly possible to see the data in context.

While this sounds complicated, you can actually build a digital twin in just a few steps:

Capture your space using the Matterport Pro3 camera and the Matterport Capture app to scan your environment in 3D.

Upload your scans to the Matterport Cloud where AI automatically processes them into a navigable digital twin.

Customize your model by adding tags, labels, and media, or blurring sensitive areas directly in your twin.

Share or integrate your digital twin via link, embed, or platform integrations with tools like BIM, CAD, or IoT dashboards.

RemSense's "Virtual Plants" show this approach in action. By putting all data in "a Single, Three-Dimensional Space," they let remote teams access complete facility information. This includes equipment docs, maintenance history, and live operational data in an easy-to-use visual format.

5. Workforce skills and training

Even the best IIoT system needs people who know how to use it. Start by checking what skills your team has now and where they need training.

Common skills needed for IIoT include:

Understanding and using data

Network setup and security

Sensor setup and maintenance

Connecting different systems

Preventive maintenance methods

Create training that addresses both technical and practical needs. Your tech staff need hands-on experience with the systems, while operators need to learn how to use the data to make decisions.

Cisco achieved a 40–60% reduction in training costs by adopting virtual training methods, including AR training solutions that let staff practice in realistic virtual environments. By letting staff practice in a virtual facility, you can speed up learning and improve how well they remember what they've learned.

6. Security for industrial IoT systems

When you connect critical systems to networks, security becomes vital. IIoT systems face unique challenges, including older systems with few security features and physical access issues.

Do a thorough risk assessment for all connected systems, looking at both digital and physical vulnerabilities. Document possible attack paths and how they could affect operations.

Separate your IIoT systems from regular IT networks, and limit access to only what's needed. Make sure all your devices use encryption when sending data.

IBM's research found that 84% of organizations with IoT devices had at least one security incident in 2022. With more operational systems now connected to networks, protecting them must be a top priority.

7. Measure results and keep improving

To justify ongoing investment in IIoT, you need to show real returns. Set baseline metrics before you start so you can clearly show improvements.

Approach IIoT with a mindset of constant improvement. Toyota's "Kaizen" approach offers a good model you can follow, focusing on small, ongoing improvements based on regular analysis.

It’s a good idea to track both direct and indirect benefits:

Direct savings: | Indirect savings: |

|---|---|

- Lower energy use - Reduced maintenance costs - Labor efficiency gains - Better space utilization | - More equipment uptime - Faster problem response - Increased production - Better quality and compliance |

5 Common IIoT automation challenges and how to solve them

According to JLL's 2024 report, successful organizations focus on usage data as their top metric. By prioritizing insights that drive action over just collecting more data, you can deliver clear value and build support for expanding your IIoT program.

As you plan your IIoT strategy, be ready for:

Budget constraints: Start small with projects that show quick returns, then use those savings to fund more. Focus first on systems with clear benefits and measurable outcomes.

Working with older systems: Use connector tools to bridge gaps between new IoT platforms and older systems. Consider updating in stages rather than all at once.

Data quality problems: Set up automatic checks for incoming data. Create clear rules for how data is collected, stored, accessed, and kept.

Security worries: Build security into your project from the start. Include device verification, encrypted communications, and regular security checks. Keep operational technology on separate networks when possible.

Change management issues: Involve users in planning and provide training focused on practical benefits. Show how IIoT tools make daily work easier rather than more complex.

How to upgrade IIoT automation using digital twins

For a facility manager, IIoT automation gives you a powerful way to improve operations, cut costs, and enhance safety. By following the step-by-step approach in this guide, you can navigate the complexities of industrial IoT and deliver real results.

Your success depends on more than just adding sensors or collecting data. What matters is turning that data into decisions. That’s where digital twins come in. They’re not just add-ons—they’re the foundation of effective IIoT automation. By layering sensor insights over a 3D model of your facility, you get the spatial context needed to act fast, fix smarter, and plan with confidence:

Anchor automation in visual context: Data without context is just noise. By connecting IIoT sensor data to a digital twin, you turn raw numbers into spatial insights—letting you see where problems happen, not just what went wrong. This makes root-cause analysis faster and far more intuitive.

Simulate before you commit: Digital twins let you model automation upgrades, production line changes, or energy-saving measures in a risk-free virtual environment. You can preview the impact of changes before making them live—saving time, reducing disruption, and avoiding costly mistakes.

Empower teams with self-serve insights: With a digital twin as your visual dashboard, everyone—from technicians to executives—can access the same live, spatially-aware data. That means faster decisions, fewer miscommunications, and more accountability across departments

Ready to see how digital twins can enhance your IIoT strategy? Book a demo to discover how Matterport's technology works with industrial IoT systems to give you unprecedented visibility into your facility operations.