Construction Surveying: How Reality Capture Improves Workflows & Visibility

Construction surveying has come a long way from traditional tape measures and manual sketches. Today, cutting-edge 3D scanning technology has transformed the way AEC professionals capture and interact with the built environment.

Measuring is also no longer the sole priority of surveys. Modern digital models leverage reality capture to transform not only accuracy but also decision-making, collaboration, and risk management across projects.

In this guide, we’ll explore how reality capture improves visibility across the construction site and through downstream workflows.

What is construction surveying?

Construction surveying is the practice of measuring and mapping land and structures to establish accurate location, elevation, and dimensional data. Surveyors create reference points, set out building locations, and confirm that construction progresses as intended.

Modern construction surveying is a continuous practice, rather than a one-off task. It provides the foundation for every stage of a construction project, from planning to handover:

Before pre-construction / following property acquisition: Teams capture existing conditions to establish a reliable baseline for scope, budget, and schedule—especially when plans are missing, outdated, or inaccurate.

During pre-construction, surveyors assess the site, verify designs, and identify potential conflicts before work begins.

During construction, surveying ensures layouts are accurate, tracks progress against plans, and supports QA/QC to catch errors early.

After completion, post-construction surveys document as-built conditions, providing a reliable record for facility management and future renovations.

How to use reality capture technology in construction surveys

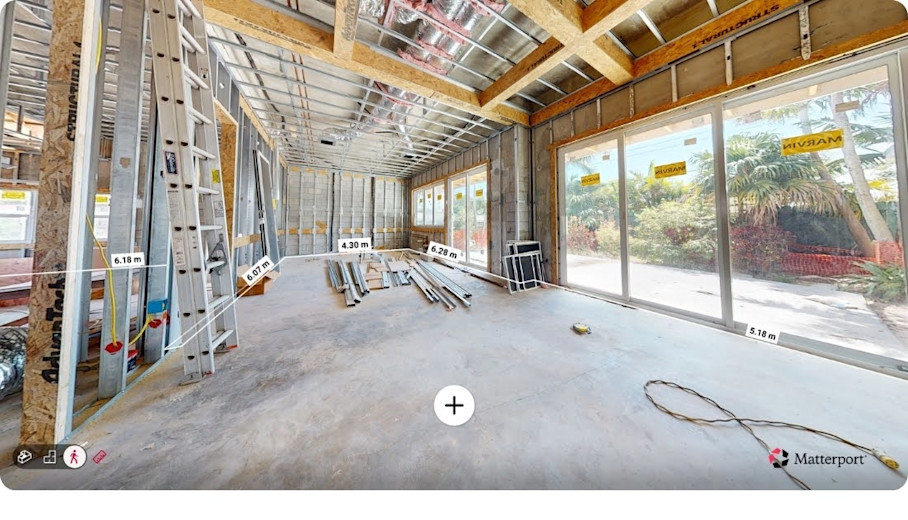

Reality capture is the process of using a 3D scanner to produce a digital 3D model of a built asset or site. Scanning a space using static, mobile, or aerial laser-scanning and/or photogrammetry techniques produces high-resolution, textured, and geometrically spot-on 3D models.

Reality capture technology fits naturally into construction surveying workflows by extending traditional measurement with visual and spatial context.

Surveying professionals use 3D scanners in both construction and infrastructure sectors to generate a 3D model by scanning sites, uploading the captured data to the cloud for processing, and sharing walkthrough models, point clouds, or floor plans with their teams.

When applied methodically, survey data moves through an entire construction project. The steps below outline how teams can use reality capture to apply survey data across active construction projects.

1. Planning & site preparation

Start by defining what the survey needs to capture: existing conditions, construction progress, or verification against plans. Identify areas that require greater detail or repeat capture over time, such as complex assemblies or high-risk zones. Clear planning helps ensure the right data is captured the first time, reducing the need for return site visits and minimizing disruption to the schedule.

2. On-site data capture

3D scanning devices capture spatial data quickly and consistently. Purpose-made hardware like the Matterport Pro3 camera allows teams to scan large or complex sites efficiently while maintaining accuracy. Capture can be completed by licensed surveyors or trained field staff, depending on project requirements. For teams without in-house resources, managed capture options such as Matterport Capture Services can help scale data collection. Speed, repeatability, and minimal interference with active work are critical on live construction sites.

3. Cloud processing and model generation

Captured data is uploaded to a secure cloud platform, where it is automatically processed into a 3D model called a digital twin. These models include measurement tools, spatial context, and optional point cloud outputs. Centralized processing ensures teams are working from the same, up-to-date dataset, eliminating version confusion and manual file handling.

4. Analysis, verification and coordination

Project teams can use the model to take measurements, validate layouts, and confirm work aligns with design intent. Point clouds can be integrated into coordination workflows for BIM clash detection, QA/QC checks, and as-built verification, cutting down on site revisits and late-stage surprises.

5. Ongoing project documentation

Reality capture data should be treated as a continuous project resource rather than a one-time deliverable. Cloud-based models can be shared with project managers, designers, and owners for remote review and coordination. The same captured data can support building and facility management processes, extending its value into handover and operations.

When reality capture is integrated, surveying becomes less reactive and more anticipatory. Teams can create a shared, up-to-date view of the site that supports better decisions before issues escalate. This construction surveying process keeps pace with construction itself, even as conditions change.

6 ways reality capture accelerates construction surveying efficiency

Modern workflows support faster execution, clearer coordination, and stronger risk control across the project lifecycle. The following benefits highlight where reality capture delivers the greatest efficiency gains for construction teams.

1. Safer, smarter site access

Construction sites change quickly, and repeated visits increase both cost and risk. Reality capture allows teams to document conditions in a short on-site window, then carry out much of the review work remotely. Surveyors and project teams can assess access constraints, temporary works, and safety risks without returning to live areas.

This approach is especially valuable where surveys must be completed with minimal physical intervention or exposure. Non-invasive or low-disturbance surveying is critical on sites such as:

Live construction zones with heavy equipment or restricted access

Brownfield sites with unknown or contaminated ground conditions

Utilities corridors where excavation poses safety or service risks

Archaeological or heritage sites where physical disturbance must be minimized

Transportation infrastructure, including rail corridors, bridges, and roadways

Operational facilities such as hospitals, plants, or occupied commercial buildings

Once captured, the site can be revisited digitally as many times as needed.

2. Faster, more accurate condition documentation

Reality capture allows large areas to be documented in a short time with minimal setup. Instead of collecting individual measurements and notes, teams create a complete spatial record that can be measured and reviewed later. This improves accuracy while also speeding up fieldwork.

Captured condition data supports:

Building condition assessments and dilapidation reports

Existing-conditions documentation for renovations or retrofits

Topographical context for construction planning

Verification of dimensions, clearances, and elevations

The Matterport Pro3 camera captures 3D data up to 100 meters away at less than 20 seconds per sweep, providing automatic measurements and floor plans.

Because measurements are taken from a consistent digital twin, teams reduce discrepancies caused by manual transcription or missed data. Speed and accuracy improve together, rather than forcing a tradeoff between the two.

3. Streamlined 3D model creation and data outputs

A single capture effort can generate multiple usable outputs without additional site work. These outputs remain connected to the same underlying dataset, which reduces duplication and interpretation errors across teams.

Common outputs include:

3D digital twins for visual reference and coordination

Floor plans and elevation views derived from captured geometry

Point clouds and BIM files for design coordination, clash checks, or as-built verification

Matterport’s MatterPak bundle, for example, provides a complete set of assets that can be imported into popular programs like 3ds Max, ReCap, Revit, or AutoCAD.

Because these deliverables are created from the same source, they stay aligned as the project progresses. Survey data becomes reusable project infrastructure rather than a one-off deliverable.

4. Centralized, shareable project records

Surveying often produces fragmented documentation spread across drawings, photos, spreadsheets, and reports. Reality capture consolidates this information into a single, visual record that remains accessible throughout construction and beyond.

Centralized survey records support:

Clear coordination during construction through shared visual context

Faster issue resolution without relying on site visits or informal documentation

Cleaner handover packages with accurate, visual as-built records

Preservation of institutional knowledge after project teams move on

Matterport Tags allow construction teams to attach text, images, and instructions directly within the 3D model. This means context-specific information—such as notable construction decisions or feature and asset specifications—travels with the model, making handover more complete and ensuring knowledge isn’t lost when teams change.

And that context doesn’t have to live only inside the model. Matterport also connects into the systems many construction teams already run day-to-day. With the Autodesk Construction Cloud (ACC) integration, teams can bring Matterport add-ons—like BIM files, CAD files, and MatterPak outputs—into ACC for easier sharing and coordination across stakeholders.

Likewise, the Procore integration helps keep documentation centralized by embedding the digital twin into Procore workflows. Teams can associate project items—like RFIs, observations, or coordination issues—with visual site context in the model, while keeping the system of record in Procore.

Because captured data persists beyond construction, it becomes a reference for facility management, maintenance, and future modifications. Instead of rebuilding knowledge during handover, downstream teams inherit a comprehensive, spatially accurate view of the asset.

5. Continuous verification and BIM support to reduce risk

Reality capture supports ongoing verification rather than relying solely on scheduled survey checkpoints. Time-stamped models provide a visual record of work as it progresses, making it easier to confirm layouts, track progress, and document quality in context.

This supports:

QA/QC reviews in context

Early identification of clashes, defects, or incomplete work

Visual punch lists tied directly to site conditions

Validating construction against BIM intent using real-world conditions

Continuous verification helps catch issues earlier—when they’re easier and less costly to resolve—while also strengthening time-stamped documentation for closeout, dispute resolution, and insurance claim support. And because Matterport integrates with Autodesk Construction Cloud and Procore, teams can log and track issues to the exact location in the digital twin for faster alignment and fewer back-and-forth site walks.

6. Long-term asset value and archiving

Survey data captured during construction continues to deliver value long after handover. Digital twins created at key milestones preserve how an asset was built, including conditions that may later be concealed.

Archived survey data can support:

Safer renovations and retrofits

Faster diagnostics during maintenance and repairs

Lifecycle planning and asset audits

Digital twin overlays, such as those offered by the Matterport & SIMLAB STAGES integration, sync rough-construction models with finished conditions. This reveals the location of hidden systems—such as pipes, wiring, and services—inside completed walls and ceilings.

By maintaining an accurate, layered digital record, survey data becomes a long-term asset that continues to reduce risk and uncertainty throughout the building lifecycle.

Everyone on a construction project benefits when survey data is not just accurate, but alive. Living, shareable digital models make it possible to review, measure, and coordinate from anywhere, turning surveys into an ongoing resource rather than a one-time task.

To learn more about how reality capture is redefining efficiency for the construction and surveying industries, watch our webinar on how digital twins streamline decision-making, reduce risk, and support collaboration across every stage of a project.